We’ve been told that we are what we eat but even heathy food on store shelves is less nutritious than fresh just picked on the farm produce. What if there were a way to offer fresh quality that was shelf stable. Would you be interested? Now you can!

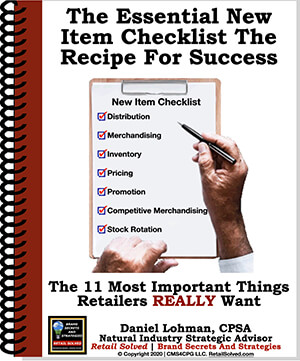

BRAND SECRETS AND STRATEGIES PODCAST #181 Hello and thank you for joining us today. This is the Brand Secrets and Strategies Podcast #181 Welcome to the Brand Secrets and Strategies podcast where the focus is on empowering brands and raising the bar. I’m your host Dan Lohman. This weekly show is dedicated to getting your brand on the shelf and keeping it there. Get ready to learn actionable insights and strategic solutions to grow your brand and save you valuable time and money. LETS ROLL UP OUR SLEEVES AND GET STARTED! Dan: One of the things that I love about natural, or as I like to say what makes natural, natural is the real creative genius that so many brands have, the creative disrupt the strategies that brands leverage, giving customers what they really want. Let me explain, if you are what you eat, and what you eat matters, people, your customers, that get that, understand that quality food matters above everything else. In other words, spending a few pennies at shelf is a lot cheaper in the long run because you're giving your body what it needs. Let me illustrate what I mean, if you get the cheap generic bread then you're hungry almost before you finish eating it if you eat the best mainstream bread you may be satiated for three or four hours. However, if you eat organic bread then you may be satiated longer if it's giving your body the nutrients that it needs to grow and thrive. Therefore, a few pennies more at shelf, that's cheaper in the long run because you're eating less bread. Dan: Now let's go one step further, the better quality organic products you put into your body they're more to sustain you, so if you eat something as fresh, or even better yet something that's created using regenerative agriculture, that could be even more nutrient-dense, so why does this matter? What if I told you that there was a creative technology that could make that level, that quality of ingredients shelf-stable? Think of the applications, think of all the things you could do to enhance the products that you make. As Gary Hirshberg once said, "The food that we eat should spoil," meaning that it doesn't have any preservatives in it. Imagine now being able to take a product that would normally spoil, usually pretty quick, and adding functional ingredients, other products to enhance it, and to make it last longer or on shelf, or perhaps even possibly increasing the nutrient value of the products that you're eating. That's what we're going to be talking about today. Dan: Before we go any further I want to remind you that there's a free downloadable guide for you at the end of every podcast episode. I always include one easy to download, quick to digest strategy that you can easily adapt, and make your own, one that you can use to grow sustainable sales, and compete more effectively with. Remember, the goal here is to get your product on to more store shelves, and into the hands of more shoppers, empowering brands, and raising the bar. If you like the podcast please share it with a friend, and subscribe, so you'll be the first to get new brand-building content as soon as it goes live. Don't forget to check out my new YouTube channel. Now here are Greg, Tom, and Richard. Dan: Hi guys, thank you for joining me today. Can you please start by telling us a little bit about yourselves, and your journey to where you're at today. Greg, do you want to start? Greg: Sure, thanks for having us, I really appreciate the opportunity. My name is Greg Newman, and I'm CEO of Desert Lake Technologies and Oregon Drytech. We'll tell you a little bit about the two companies, and how they began, and how long they've been operating, and what we do, which we have got two of my key guys, why don't you guys introduce yourselves. Tom: I'm Tom Valenzuela, VP of Operations for Desert Lake Technologies, and co-owner of Oregon Drytech. Richard: I am Richard Newman, Director of Sales for Oregon Drytech. Dan: Thank you for doing that. You guys look way too comfortable over there in the right so we'll see if we can [inaudible 00:03:20], so anyhow, so please tell us what is it that you guys do. The reason I wanted to go here is that you guys have an innovative technology, an innovative solution that is, I believe is going to revolutionize the way we think about healthy superfoods, nutrition, etc., and so let's frame it around what is the problem you guys are trying to solve, and then how does your solution solve it specifically. Greg: Right, okay. Well, we'll start with Desert Lake Technologies because, or DLT as we call it, because that's been around the longest, and actually spawned Oregon Drytech. So I'll just, at a high-level explain what we do, and how they interact. Basically, we started Desert Lake Technologies 20 years ago, and my father and I started the company, and he ran and built the company basically harvesting a very rare type of blue-green algae off of a lake in Southern Oregon called Klamath Lake, and it's a blue-green algae called AFA, and different from chlorella, different from spirulina, has properties that neither of those two have. We started playing around with harvesting, and selling wild harvesting and selling this algae, and then along the way what we've decided to do was there were compounds in AFA that allowed us to do interesting innovative things. Greg: We started coming up with ways of isolating, and concentrating those compounds, and creating new products with those. So now we have a whole host of products, some of which DLT sells in bulk, B2B to the nutritional supplement institution predominantly, and food industry. Then a couple of our products, actually we sell exclusively to an MLM company called Cerule, and Cerule sells those products to the general public typically in capsulation form. But one of the key things about being able to save those compounds, and not kill them off in the processing was the drying technology, and basically, most of the current drying technologies that existed 20 years ago used a lot of heat, and did an effective job of drying products, but killed flavor, nutritional content, and color. So we had to come up with ways of drying, and we did so. Greg: We innovated some interesting dryer technology, and about two years ago, two and a half years ago Tom and I decided to spin the dryer company off as a separate company, and we started offering toll drying services to the food industry, nutritional supplement industry, and even the pharma industry. Guys, did I miss anything? Tom: That's pretty much it. Greg: So we started toll drying for these companies where they send their product to Klamath Falls here in Southern Oregon, and we ran them on our dryers. So we have a dryer farm, that obviously we use for our algae, but we have a lot of extra capacity on those so we're filling them up now with other products from customers around the country, around the world actually. Along the way, we've been approached several times to sell our dryers or to manufacture and sell them, and so we started working on that. We've got ... We haven't done it yet, but we have, I don't know, five or six companies around the world that have shown a lot of interest in buying our dryers. Again, this is a really unique dryer because it does a gentle drying of the food, or nutritional supplement products without destroying the nutritional value, or the flavor profile or color profile of the product. Dan: Thank you for going through all that. So there's a lot to unpack there, so let's just dig into it. What are the three different types of algae again that you mentioned, and what's unique about them? Why does it matter? Why would anyone listening to this care? What I'm getting at here, Greg, and thank you for going through that, is what are the unique properties that you are isolating based upon what you're harvesting, and then why is it relevant to me as a consumer, and how was that going to change [inaudible 00:08:31]? I know there's a lot there so if anyone wants to chime then go ahead. Greg: Great question. Dan: Yeah. Greg: Yeah, great question. So basically the three kinds of blue-green algae that I mentioned where chlorella, and spirulina, those are the two best known, and they're popular, you can walk into almost any grocery store, and find them on the shelves. A third type is commonly referred to as Klamath Lake Algae, and you can find that on some grocery stores, but while chlorella and spirulina can be commercially grown, meaning they can be grown in ponds anywhere, almost anywhere in the world, AFA or Klamath Lake Algae cannot, it can only be wild-harvested. It's only available in a couple of locations throughout the world, and Klamath Lake is the only location in the world where it can be harvested, where the infrastructure exists to be able to actually harvest it. Greg: The other places, there's a lake in Iran, which makes it a little tough for Westerners to get in and harvest. Then there's also one in Kazakhstan, again a little hostile, and no infrastructure whatsoever, no roads, no electricity, it makes it pretty tough to get in and do it. So Klamath Lake is really the only viable option or one of the few viable options in the world where you can harvest this stuff. The reason people should care is the interesting compounds that exist in AFA, Aphanimon flos-aqua is the scientific name, that's why we call it AFA, and basically it has a couple of compounds in it that don't exist in the other types of blue-green algae. For instance, it has PEA, Phenylethylamine, which is the love chemical in our brain, it makes us feel better. It's what it's in chocolate and other things that people [inaudible 00:10:48], but it's a very powerful compound on providing neuro health. Greg: There's so much scientific evidence out there about that, and one of the interesting things is AFA is loaded with PEA far more than what you get by eating chocolate. So if chocolate makes you feel good, AFA should make you feel incredible. It helps, it's been clinically proven to help with a lot of neuro imbalances. So we talked a lot about it helping with anxiety, and with general mental balancing, and we've had a lot of anecdotal reports about that throughout the world. Then there are also other compounds that are incredible immune boost properties within AFA far more than what you get ... spirulina and chlorella will have some immune boost, but we've clinically shown our AFA, blue-green algae to have far superior immune properties that help balance, and really increase your immune response, and of course, right now given our environment, and what's going on, I think we all need a healthier, better immune system. So AFA is a phenomenal immune ... has phenomenal immune boost properties. Greg: In general, that's what you get with AFA, what we've done is we've actually isolated some of these compounds, and extracted them, and concentrated them into separate products. So one product that we did for instance, that Cerule sells exclusively, is a stem cell product called StemEnhance. We isolated three different compounds out of the algae, concentrated that, and have run double-blind clinical studies, multiple, and have published papers, and patents on this product that boost the stem cell migration in your body, so it enhances your body's natural stem cell creation, and circulation of those stem cells. It's been shown on average of about 30% for people. So you take it, and there's a stem cell, a measurable stem cell response within, usually about 30 minutes, 45 minutes of taking the product, and it lasts several hours. So that's been clinically proven that our product does that. Again, that's a Cerule product called StemEnhance. Greg: There is another compound that we've isolated out of blue-green algae called phycocyanin, or what we call PC for short. Again, we have two products, we have a bulk product that we sell out of DLT to companies called CyaninPlus, and then we also have productized this with Cerule in a product called Cyactiv, and what that is, is a whole-body inflammation management product, and it's been again clinically proven. We've done clinical studies, double-blind placebo-controlled studies, have published papers, and scientific journals around phycocyanin in being a phenomenal COX-2 inhibitor, and 5-LOX inhibitor, and not to get too technical, but there are multiple pathways of inflammation in your body. Inflammation in general causes is the root cause of a lot of other diseases, heart disease, and even has been determined to be a major issue with the COVID-19 virus going on, inflammation alone is kind of where that COVID-19 settles. Greg: Having the tool that helps manage inflammation throughout your whole body is key, and CyaninPlus and Cyactiv had been shown, proven clinically to reduce whole-body inflammation, and help manage that in two of the normal three types of inflammation pathways in our body. It does so without the side effects that you get from over-the-counter medicines like ibuprofen, and things like that, those are effective at shutting down one of the pathways, COX-2, but Cyactiv, and CyaninPlus are able to actually control two different pathways. Dan: Cool, and thank you for sharing. So would you please give me links to [inaudible 00:15:52], and stuff like that, so that I could put that in the Shownotes, and the reason- Greg: You got it. Dan: Yeah, thank you for doing that. So let me kind of dumb this down, because that's really, I mean there's a lot of information there. So I make the reference that if you are what you eat, and what you eat matters, and if you believe what you eat matters then eating the better products is better for you. So I always use the analogy that if I go in, and I eat the cheap organic, I mean the cheap generic bread, I'm hungry before I finished eating it. If I eat the best whole grain bread I maybe satiated for a few hours, but if I eat the best organic bread, and if I believe that I am what I eat then those extra nutrients are going to fuel my body longer, therefore I'm going to be satiated longer, therefore I'm going to get more benefit. The point here is that even if I'm spending more at shelf for that bread I am getting a better product as a result, I'm getting better value. Dan: So what you're saying, to kind of put it in your context, is that if you're eating the best, purest ingredients, then you're going to get the most benefits. So let's back up way far, so one of the things ... I've done a lot of work within the supplement category, and I think a lot of people don't understand that when, even if you take whole food supplements, whole food ingredients, and you put those together at high heat or pressure, the heat actually bakes up the nutrients. The process of capturing the ingredients that a lot of companies use, those are not as pure because of the way that, like you were saying, the dryer, that overheats or overcooks if you will, the wrong terminology maybe, the ingredients. Dan: So the best way to get the ingredients out of it is to use the slow drying process, and here's where I'm going with that, so I [inaudible 00:17:48] it, I did a lot of work with MegaFood, and they've got an amazing way of extracting the benefits of products, of whole food supplements, and adding that into their product without using high heat pressure, etc. So they are the equivalent of what you're doing, although you're doing a lot more, and a lot better obviously, but my point is as a point of illustration that because of the way that they produce their products I have a really good understanding of what you're saying generically. Dan: Now we'll take this to the next level, so to kind of explain what I'm getting at, a lot of companies bake what they're creating, and they bake it not only in an oven or a dryer, or something like that, but because they're trying to speed up the process of whatever they're trying to do, that cooks out the ingredient. So when you're talking about your dryer, anyone who's listening ... First of all, if you've got a link that we could get to, that we could share as to how the dryers are actually working, I'd love to show your technology. Certainly, MegaFood has the same thing, but the point and this is not a commercial about MegaFood, it's just an illustration, but the point is if you're taking a long time to slowly dry something then you're leaving all the nutrients, and you're pulling out the water. Then you've got a powder that is extremely nutrient-dense, that does a lot more for your body. Dan: So back to the bread example, if I'm ingesting your product I'm getting a lot more benefit than I'd get beyond the other products, not to mention the fact that the algae that you're extracting is far more potent, as you've illustrated than what else is out there. So can you comment on that, and maybe help bring that illustration to life? Do you have a way to, a link that someone could go to, to kind of get an illustration of how this works? Because it's very scientific, but the simple fact is that this is the best way to get the best quality results of the best quality nutrients. Greg: Yeah, you're exactly right, and I'll ask Tom and Ric to weigh in on something in a second, to talk a little more about some of the companies we worked with, and have been talking to. You mentioned MegaFoods, and those guys are using a similar technology that they bought years ago, and they do a fantastic job of everything I hear. It's the technology itself, the drying technology itself, you can read about on the desertlake.com website, and we call it the hydro dry. We've since created a new version of the dryer, and so Oregon Drytech calls that the Enviro Dry, the new version, and there's a reason for it that we'll get into in a little bit because we've innovated some new other key features that we found our customers are extremely interested, and making sure that we had. Greg: The idea here is it's a slower drying process on purpose, and you nailed it on the head. The reason it doesn't have the throughput that for instance other drying technologies like spray drying has, is because we're drying things at a slower pace in order to preserve the nutritional content, the flavor content, the color content, things that are important to our customers. So really it's not a technology for every company out there, there's a lot of companies that pump out, to your reference, not very nutritious products, it could be a bread that is just ... they don't care as much about the quality, the nutritional content, the flavor content, and so they can use other types of drying technology to get there. But if there's a company that really cares about the nutritional profile of their product or the flavor profile of their product ... Tom and Ric, maybe you guys could talk real quick about, obviously not mention any of our company, our customers by name because of confidentiality, but give a profile of one of the companies that we've been working with from California. Tom: Yeah, due to mutual nondisclosure agreements we can't actually mention names without their permission, but in general it can be ... we typically work with organic food companies, those are the folks that we find, their ethos aligns very well with us. At Desert Lake Technology we are super concerned about the absolute quality, that's paramount to anything else even throughput, but even though we've made massive improvements to the drying technology to improve the throughput for the folks that are always considering the cost of goods their cost. But if it's organic ... it doesn't have to be organic, but if the quality is the very first part of the equation that you're getting into, any fruit, any vegetable, we've even done meat products from overseas that showed up in puree form, and we were able to successfully dry that, and literally on the ingredients package that they have, we use absolutely no preservatives whatsoever, nor our carriers on some of them. Tom: Now higher fructose say sometimes require organic carrier because of the binding qualities, so that's a scientific thing, a scientific deal that we can [inaudible 00:24:05] with, but we found ways to successfully dry those items, or those products on behalf of other companies at an industrial scale. When you read the back of the package there are no other ingredients, there are no three-syllable, four-syllable words that nobody understands that in terms is something either synthetic or a way of preserving that product. We can take an organic fruit, vegetable or meat, and without adding anything to it, give it a two to five-year shelf life with zero preservatives. Tom: Now it sounds like the folks that are following you, or watching your podcast, that should be a big deal to people. There's a lot of companies out there, and a lot of folks that, especially during these times eating the best possible food that's unadulterated should be at the forefront of what they're doing because everything counts. It's not only the supplements that you take, but it's the food that you are mentioning that you need. Everything counts in it, and if you can ingest things that are going to be the healthiest for your body then your immune system has no choice but to boost itself. Tom: So we've always, that's always been our ethos, with the algaes that we work with it's very finicky, algae is very difficult to work with that's why there aren't a lot of companies that successfully got it. I would say when it comes to processing AFA algae there's nobody better in the world than us, and because of the ethos that we've always followed, Greg and his father Howard, who founded this company have always made that a point for any of our processes, that it either has to follow organic GMP qualifications or also Halal Certified for the Muslim world, and we're also Kosher Certified for the Jewish world. So we were kind of following I would say a scientific, hippie way of doing things way before it was cool. Dan: I love that, that was good. Well, and thank you for sharing that, and to back up a little bit, and I know I keep saying that, but I think I was sharing with you guys on the call when we talked previously, that I'm actually the founder in an organic sweetener company, which is really cool, part founder, one of them, so I had to learn a lot about spray dry technology, and stuff like that. If you can imagine spraying something out of a garden hose, but atomizing so you've got the droplets, and then drying it before it hits the ground, and so then again you've got the high heat, and so that's what you're talking about there. Dan: Now when you're talking about, and I'm sorry I forget the term, the combining, what was the term you used, Tom? I forget the term, you heard it a lot of times when you combine two things together, the glue that sticks it together? Richard: The binding. Tom: When they tend to bind together. Dan: Yeah, there's the term you use, I forget, anyhow, so I'll go back in. My point is the fact that you guys can isolate the product itself, and then put it into a raw package, that's fantastic. So one of the reasons why I was thrilled when you guys reached out to me, and why we're so aligned in having this conversation, is because a lot of brands are trying to think of innovative ways to change the market, change the way we think about food. Dan: Plant-based is such a big trend right now, and the challenge when you look at organic, and you look at other products that are out there on the shelf, the shelf life is extremely short because quality foods should spoil. That was another reason why I was so excited about what you guys are doing, so imagine going out and buying your favorite organic product, that is actually better for you because it's more nutrient-dense based upon what you do, and then in addition to that add a shelf-stable component to it that does not add any chemicals or anything to it that pulls out the nutrients. Can you talk about that? Because that's really revolutionary. Tom: Yeah, one of the things that we've been seeing, that our customers care about is exactly what you just pointed out. They're looking for ways to create shelf-stable products to give them longer, to be able to sell it, to be able to offer it to customers. We turn things into powders basically, so we can take food products, and we've been doing this a lot, you name it, strawberries, mangoes, we've done celery, and spinach, and kale, and beets, I mean you name it, we've been drying it on our dryers recently, and we create powders. Tom: Now why would a company want to take their fresh spinach, and turn it into a powder or their fresh mangoes, and turn them into a powder? Well, if you think about it for a while you've got an opportunity there to create a new product category, and you have a way to lengthen your sales cycle. So usually if you're selling a fresh product you've got a certain number of days to be able to pick that product and move it to a grocery store, somewhere where you could sell that product fresh, after that it goes bad, and you've lost whatever opportunity to be able to sell the product. Tom: So being able to take this process, and by process, I don't mean by using artificial means or anything like this, I'm simply talking about taking the product ... Here's what we did with mangoes. We take the mango, we puree it, which means we put it in a super blender, and create a paste, and make it the right solid content density so that it sprays onto our dryer appropriately. It goes through our dryer tunnel and comes out the other side a powder, which we then ... we usually bag, vacuum seal, Mylar bag the product, and we keep the moisture content very low, and with that, no bacteria can grow within the product. If your moisture content is set at a certain level there are no bacteria than can grow. So that's always what we're doing, we're making sure that the moisture content of our final product, when it gets bagged is a product then that has a shelf life of a couple of years. Tom: Now that farmer has the ability to sell that product over an extended period of time, and that's very attractive to a lot of these customers. Also, if they sell it, let's say overseas, there's a huge market in Asia for produce, and other things grown here in the US, the ability to ship it without shipping water, without shipping ... they used to can things, and send the cans over, well, that locks in a certain level of shelf life for sure, but usually, you have to have preservatives to be able to extend that shelf life, number one, and number two, you're shipping a can with a bunch of water, which is expensive. So they love the alternative of being able to just ship the product, and still have a two to five-year shelf life depending on the product, and get it to their markets in Asia, who then, in turn, use it for their food products, and food production whether it's putting it in a smoothie or a recipe of some kind. Tom: We've even done products ... There is a company that makes organic soup, and we dried their soup for them, and then they were able to actually sell it in packets to their customers. We're talking to companies like spice companies that are interested in ... If you're a spice company what do you care most about? The flavor. Well, drying it with spray dryers or drum dryers kills a huge amount of that flavor, so being able to dry it on our dryers are not only going to lock in whatever nutritional benefits that these spices have, but also the flavor which is what everyone cares about. So there are so many different companies that have ... we've been interacting with since we started Oregon Drytech, that we're very excited to work with. Tom: We're actually running a test on coffee here pretty soon as well. If you think about coffee most of the powder or dried powder that you can buy on grocery stores is either freeze-dried or spray-dried quite honestly, and the quality of it is not very good, which is why we would rather go to a Starbucks or a Pete's Coffee, and get a high-quality product that tastes good, than having a can of Folger's in your cupboard. But being able to utilize new types of drying technology, we believe we can create a coffee product with a partner that we're working with, that's going to be far better than what exists out there today as far as a powdered coffee that you can do, short of buying the beans and grinding it fresh yourselves. Dan: I love the way you- Richard: [Inaudible 00:34:34]. Dan: Go ahead, please do. Richard: [Inaudible 00:34:34] in somebody's purse or their wallet, not their wallet, but in their pocket that they can carry around 10 cups of coffee, that they could either be in teabag form or just a safe pack that they dump in boiled water or hot water and mix, one, not as expensive, two, easy to carry around, and three, if you're properly locking in the flavor profile I think it's the difference between just having a regular cup of Joe in a café that taste just like any other café, or being able to bring out the true flavor profile of a Columbian or an African coffee or something like that, it would be a major difference. Tom: Not to mention the antioxidants that stay in it with the right drying technique because of [inaudible 00:35:21] often you lose everything nutritional in it. Dan: Thank you for it, actually, and I'm so glad you'd said that. I'm sorry, go ahead, you were going to say something else. Tom: No, I want to say it's really exciting for us to start that project, to do that. Dan: I think it's great what you guys are doing, again this is why I love their technology, and to kind of frame this to help people understand it, I mean to kind of make it really super simple stupid so people like me can get it, just kidding. No, I get it completely, is I remember when I worked for Unilever many, many years ago, and at the time Wisk was the number one detergent in the country, and Wisk went to a three-times concentration. So you had a big bottle, and you went to a small bottle real quick, and the consumer didn't understand that that was the same thing, that's why the product failed. But the point was, the amount of product that you could put on a truck, and ship because of all the water that you're shipping, think about all the soda companies, that all they're shipping is water, etc., etc. Dan: So to reduce that now let's put that in today's terminology because of what's going on with COVID, and pandemics and stuff like that, I went out, bought a bunch of produce before this happened, not knowing that this is going to happen, and the challenges are now if I want to go buy more produce I've got to physically go into the store. Well, that's not a good thing if you're older or immune-compromise, etc., but I can have that same quality as if I had planted it myself, and it was regenerative agriculture. Let me frame it this way instead, one of the things that I focus a lot on this podcast is that quality, the difference between the quality. I'm talking about this as being sort of the ripple in the pond, and so the customers that get what we're talking about, that's where the ripple begins, before it becomes a tidal wave and ends up on a [inaudible 00:37:16] shelf, or a tsunami and ends up on a Walmart shelf, in terms of illustration. Dan: So going back to the bread example, if you are what you eat, etc., so regenerative agriculture produces a far better product that's more nutrient-dense than something else, and there are a lot of other products, and that has a lot to do with the quality of the soil, the quality of the air, the quality of the water, etc. There are a lot of components in there. A lot of people think about where their food comes from, and how it's produced, etc., so if you're producing a product, a food product, corn does it matter, and you're using dirty water then the quality of your product is not going to be as good. Think about the difference between a $3 bottle of wine, and a $3000 bottle of wine, how about we use that idea? So what you're talking about is being able to create that $3000 bottle of wine in terms of that's what these companies are taking, that quality of an ingredient. Well, what you're doing is you're extending the shelf life, you're saving or protecting those ingredients in their best form so they're pure as can possibly be. Dan: Then to your point, Tom, now I've got the ability to have the convenience of getting it anytime I want, and to your point, Richard, I've got the ability to have the higher quality, the things that you would typically lose as you're processing things, processing meaning no matter how you make it. Again, that's why this is so critically important that people understand what this is, and how this works. Dan: Now the other reason this matters, going back to that ripple in the pond is as consumers are looking to healthy products, especially now with what's going on with COVID everyone needs to eat. The best defense as you talked about a minute ago, Greg, is the best defense against COVID or any illness, it doesn't matter what it is, is a nutritious diet. So if we can help people get a nutritious diet that's more convenient, that's more cost-effective, that's more everything else that we're looking for, that it's on-demand, etc., and yet maintain the quality of it at the level that you're maintaining it that's the win-win. By the way, these are the trends that are driving sales across every category, across every store, across every channel. Dan: Let me illustrate that. Several years ago I wrote a feature article for the 2016 Category Management Handbook, and Nielsen gave me access to all outlet data, and it was amazing what they're able to provide me, which is really cool. What I was able to do is prove a theory that I had, and so let me illustrate it this way, TotalBerry was up 1.5%, that's a multi-billion dollar, all outlet, every outlet category, so TotalBerry's up 1.5%, Organic Dairy was up 12.4%. Organic Dairy represented 9.8% of that pie, a small sliver of the pie, right? That small sliver of the pie, if you remove that then TotalBerry would be flat, it would only be 0.5% If you look at plant-based, Kosher, gluten-free, it doesn't matter, that's even more compounded. Dan: Now, we get into plant-based, and we're talking about regenerative agriculture, these things, these ripples in the pond as they're beginning to form, this is what's driving sales across every shelf. The reason people need to be paying attention to this is that we're giving people the technology, to skate to where the puck's going, and not skate to where the puck's been, or as I like to say when I'm talking about big brands, what they think is innovations changing the labor and something, and it's really not innovation. People are keen on that, they're aware that that's just this a ... I don't know, it's a scam, I don't want to say a scam, but it's not [crosstalk 00:41:15]. Exactly, thank you. Dan: So this is what we're talking about in terms of creating that unique opportunity for a brand, to differentiate yourself, take a leadership role in the category, and that drives sales throughout entire categories, channels, retailers, etc., and this is what customers are looking at. I mean thank you guys for what you're doing, it's really cool, any thoughts about what I just said? Greg: I think you're right on, Dan. I think the most important thing right now is that we're working with a lot of companies that I think really do care about exactly what you're talking about, and that's their focus, that's what they are trying to achieve, which is why they're looking for innovative ways to get there. Both DLT and Oregon Drytech represent noble new ways to be able to arrive at that location that you're talking about. So they're looking to create new products, they're looking to be able to offer consumers products that enable them to get that nutrition that's so important to get. Greg: Now we talked about working with farmers in California or whomever to create, let's say spinach in a powdered form that we put it in a bag. How is that going to impact your general Joe public out there? Well, what we're not saying is that you're going to have that at your home in a kilo bag of dried spinach, and that's going to replace the salad that you go and buy at the local grocery store. But what we are saying is that there are innovative products coming out that you will be able to get that same nutrition content in a powdered form, that you can add to your smoothie or that you can ingest in other ways by sprinkling it on other food products. Greg: Things like that, that become an innovative way to still be able to get that nutrition, and help boost that immune profile in your body, either by swallowing it in a capsule, or sprinkling it on soup, or sprinkling it, putting it in your smoothie, or whatever, there's going to be innovative new ways to be able to utilize these products, and get that nutrition content into our body to help boost our immune system. Dan: Which is exactly where I was going with this, so thank you for sharing that. If you think about the fact like a lot of people, you were talking about making a dried organic soup, which is really cool, I want to know how to get some of that. But one of the things that my wife does amazing with, it's so amazing, she takes things like that and adds it to existing products. So we're talking about functional, and what I'm getting at there is you've got a healthy product, a healthy soup or something like that, and you add a dried something to it to enhance it or to make it even better for you, you make a smoothie. For example one of the things that I've been doing is I drink a lot of whole fruit type supplement, I put a lot of whole food powders in some of the drinks I have because it boosts my immunity, and so and so forth. Dan: Obviously I'd like to have something as pure as you, and we're going there, but what I'm getting at is that this is the future. So one of the key things that people are trying to do, one of the key trends also are functional ingredients, and so if you've got an energy bar that's pretty amazing as it is, and now you can add the AFA or something else to it, then you've enhanced the functional ingredients of your bar. Again, it's that ripple in the pond that's driving sales across everything, across every channel, that gives you a unique competitive advantage. Then when you go to your retailer you can leverage the consumer that gets it, that understands it to drive sales at shelf. Dan: Retailers want three things, more profit in their store, they have more foot traffic in their store, I mean a reasonable profit, more traffic in their store, and then they want growth in the category on a competitive advantage. So if you can offer a retailer two of that by leveraging that unique property that's in your ingredients, in your package, that's going to help you, and that's my secret sauce. That's what I help brands do, is take your stories specifically, and bake that into what they're doing, what they're offering, so instead of just looking at things from the commoditized standpoint, male, female, this is [inaudible 00:46:17], whatever, we're actually getting to the nutrient profile or the attributes that are actually driving those trends at shelf. So thank you for sharing that. Dan: When you're talking about your dryer technology, and this is another cool thing that you mentioned that I love what you guys are doing, again we're talking about people used to bake, they used to cook it or whatever, that you cook out the nutrients, some other people that are using different versions of this, it's not quite as efficient. So can you talk about your dryers, what's unique about them, and how your dryers are more efficient? Then if you can, kind of weave in your story about the special boats that you made, that created ... that you use to harvest the algae to be in it because ... and I want people to think that you're out there with a fishing pole. I'm just kidding, but how do you skim a lake, and get what you need, and not what you don't want? Greg: Yeah, it's not ... this is definitely going out and harvesting algae is not, you don't take a net, and go out on a boat, and just scoop it up. That would take a while. So a long time ago we started working on building specialized harvesters, and so as part of that, we had to build our own manufacturing, engineering, and manufacturing capacity in-house. So we brought some super-geniuses on that we love, our engineering team that all work for Tom and they started building these special boats, and then also were the ones that started building our dryers. Well, I'll let Tom dig in, and answer your question a little more about what is special about our boats, our harvest boats, and the process that we go through. Greg: One thing to maybe talk about, Tom, also is the new Enviro Dryer from Oregon Drytech, and what's so special about that, because, well, we've talked about our dryers in general, what we do, low gentle drying with low heat, and low moisture content. The new dryers have a number of specialized features that really help in achieving those goals, and so I'll let Tom talk about the new Enviro Dryers in a second, but one other thing I wanted to go back to though is just in emphasizing the point that you're making, we're a ... DLT and Oregon Drytech are B2B companies, we don't sell our product directly to consumers, but we work with a number of companies that do. Greg: I mentioned Cerule, that cerule.com, C-E-R-U-L-E, is the name of the company, and they take our products, and productize them, along with some other products out in the market, and create some phenomenal products that are sold directly to consumers. Then a lot of our other customers are doing the same as well, and some of them we can talk about, and some of them as Tom said we're under nondisclosure, and without their specific release and okay we can't mention who they are. But we're really excited, the more that we start doing this with the dryer technology, to see these companies come, they're coming to us out of the woodworks, it's crazy. We've got a company out in Canada that's doing blueberries, and they're shipping their blueberries all over the world, and they've decided, "We can ship blueberry powder. It would be cheaper, better. It would last longer at the shelf stability." So they have started doing that with their blueberries. So we're super excited to be able to support them. I think pretty soon we'll be building a couple of dryers specifically for them that we'll be installing up in Canada, which is awesome. Greg: So there is a number of these things that we're really excited to start seeing finally get out in the marketplace. So you can get products that are using this technology right now from Cerule, and then other products are hitting the market pretty soon that you'll start seeing products hit the market that was made with our technology. But going back to what you're asking about maybe Tom can jump in, and talk about our harvest technology, and what we do, and then the new Enviro Dryer from Oregon Drytech. Tom: Certainly, thanks, Greg. Yeah, now you're getting into my core competencies, which is exciting for us. If you were to go out into the marketplace and try to find a company that manufactures on industrial scale algae, there is none. There is no Amazon that we call for algae, there is nothing that gets delivered to us. We quickly found that vertical integration on our part by definition is hiring everybody that we need to bring in-house and control good quality at which we put our products became paramount for our business model. Tom: So we brought on ... We're very robust on the science side, so on the food technology side, we're super heavy on the science side. We approached everything from a scientific point of view, but when it comes to actually build things that we need or retro-fitting things that are necessary for us to maximize the quality of our product line we have to bring it in-house. Howard Newman and Greg were very, I guess innovative in thinking that's what we need to do. So anyhow that's what we did. We went out and found the very best fabrication folks that we could in the marketplace, brought them in-house, and created three different methodologies for taking algae out of the way because all of it has to be on an industrial scale. We do hundreds of thousands of gallons worth of algae a year, and you're not going to do that with a net or a five-gallon bucket. Tom: So one of the methodologies is a vacuum system that we use. All of these are very dependent on the environmental conditions of the lake. We harvest a wild harvest. We have no choice what the environmental conditions are, all we can do is contour to whatever those are. So the three different methodologies that we use are our vacuum system, the lake has to be dead flat, there could be no wind whatsoever out on the lake. By using that, that garnishes a very large quantity of algae in a day, we can basically vacuum about 50,000 gallons a day if the conditions are correct. We also use the string harvesting methodology, that actually Howard Newman, Greg's father invented while he was fishing on the bank of Klamath Lake, and [crosstalk 00:53:30] he found that certain ... Go ahead. Greg: You jokingly said that, and I was chuckling inside, but about fishing for algae, and that literally was what happened for the string harvester, is my dad was fishing on the lake, and as he pulled up the line he noticed that the algae stuck to the fishing line. That gave him an idea, and so they started playing with it, and that led to one of our key innovations on harvesting algae on the lake, which is called our string harvester. So go ahead, Tom. Dan: That's a great story. Greg: Sorry for interrupting. Tom: Yeah, no, no, that's a great interruption because that's literally ... he was fishing, and the guy was, his whole life was in a constant state of research and development in the nutraceutical industry, so for him, he saw something that nobody had ever seen, and what he found is just the physicality of the AFA algae tend to cling to a string, or a certain test line, where all of the other algaes that happen to grow, that aren't so positive would have very negative traits out on the lake fell off of. So it was also a natural filtration that we could kind of do prior to hitting our food process that is on the way. So that's the two methodologies. Tom: The third one, and the most innovative one that we recently, our team, strictly our fabrication team came up with, and proved the concept, is a skimming process, where actually the algae that grows on the lake is a surface algae that grows in the top column while the sun is out, and when it blooms we have the ability to just skim it along the lake. But now the conditions almost always have to be ... they don't have to be ideal, but they don't have to be dead flat, but that ends up right now being our best methodology for extracting algae from the lake, and all of those innovations happened in-house here. Now since then, there's been a couple of other companies that have kind of pseudo-copy some of the things that we did because it was industrialized and brought out large quantities, and we're okay with that for the most part. Tom: So that pretty much talked about what happens on the lake, those are the three methods, we have the string harvesters, we have the vacuum system, and we also have the skimming method. But most excitedly is we've gone through lots of iterations, and versions of our Enviro Dryer, and what we're most excited about, and what we heard in the marketplace, even from people that you've mentioned, is the difficulty that every company has to depend... it doesn't matter what the methodology of drying is, if you don't have the ability to control relative humidity then that's where most of these companies are finding degradation in their ability to preserve their food. The more moisture in whatever you're packaging the more opportunity that [inaudible 00:56:47] essence and bacteria growth occurs, and that's where we really are most excited. Tom: We have created ... the reason we call it Enviro Dryers is we actually encapsulate the dryers inside of a room, think of either refrigeration or freezer panels that are pretty GMP certified, and we absolutely control the relative humidity inside of that box. We also put air scrubbers in there that keep the air particulate as low as possible. We wouldn't call it a clean room, but we would say we're just short of cleanroom. It scrubs the air, and changes, exchanges all of the air inside of that box five to six times an hour, so you can imagine if you warm that room up, and turn on the dehumidification in it, and within an hour you're ready to roll. The product coming off of the dry end of that has to chance of reconstituting itself because you happen to be manufacturing on a day that is high in humidity. Tom: So those are some of the major problems that we saw in the marketplace. We put our team on it, and it took a couple of years to figure out, but we finally figured it out, a way of circumventing the biggest problem that we found out there, and which really has stepped up the ability for us to dry these organic [inaudible 00:58:19] with no preservatives, and give them shelf life at ambient temperature, which is super important to know. So a lot of these ... There are some products that do need to be refrigerated and frozen, but the majority of what we dry can be dried, and stored at ambient temperature. Dan: That is so cool. Greg: Just to add one more point to what Tom was talking about with the Enviro Dry features. So what happened was we were drying things, and as we were measuring the moisture content of what was coming off of the dryers, it was perfect. It's below 5% moisture, and that's kind of the target, and that would be perfect, but over the course of a couple of hours that dried product is coming and collecting into a bag, and after a couple of hours that bag is collected, and then moved on to processing where it's tested again, and lo and behold, wait for a second, the moisture content jumped up to 10. Wait, what's going on? Well, if you've got a high humidity day, and that super dry product is sitting in a bag, guess what it's going to do? It's going to start sucking moisture out of the air. Greg: So then while we're testing it, [inaudible 00:59:34] measuring perfect, but because of the ambient environment we would notice that we would run into problems with keeping that moisture content at those ideal levels. So by creating a box around the dryer, or room around the dryer where we literally can control the environment, and where we can actually keep it nice and dry, and the relative humidity super low, now that product could sit in there for the several hours that it needs for us to collect enough, without having the problem of its sucking up ambient moisture out of the air. So that was the purpose, is being able to control the ambient environment with something that nearly everybody we talked to complained about. We experienced it ourselves as well, so we're also fixing our own problem, but in the meantime, we think we have addressed a major problem in the market that we're really excited about. All of these is in the process of patent-pending, and so we've got a lot of very exciting patents that we've been working on for a while that we think will be very important for us going forward. Dan: Well, what you guys are doing ... Go ahead. Tom: Yeah, Greg puts an exclamation point on what we heard from the industry, and we tried to address it. It wasn't an easy thing to address, we went through about six iterations and revisions on what we finally send it on, and once we send it on we have approved the concept. It definitely exceeded what we had as a minimum expectation, and it just blew past it, the product is second to none, [inaudible 01:01:38], and really speaking of the nutshell of what we do, then I would say we take an organic product without decimating or massive degradation to the flavor profile, aroma, and color, and we take it to a level of dehydration that self-preserves. We keep temperatures very low. We do exceed 150 degrees Fahrenheit, which is the actual kill step that keeps other bacterias from growing, that's required by the FDA for [crosstalk 01:02:13] certification. Tom: Then now that we've completely controlled the environment as it comes out of the drying mechanism, there is no additional hydration or ambient humidity in the air to take, what we've taken almost the 2 ½ % moisture content, which is super low, no bacteria can grow in that area, or dry of an environment. So there's no ... and you can imagine something that's that dry, and that dehydrated that it becomes very hygroscopic, almost a sponge, it's just looking for moisture in the air, and we have just negated that. There is no moisture in the air. So that's what really sets us apart from other folks, for both preserving all three of those qualities that we've mentioned multiple times, and absolutely controlling the relative humidity coming off of at the end of the mechanism. Dan: Cool. I spent a lot of time focused on packaging, and so we do talk about some of the issues that brands run into, and of course, everything is ... moisture is the devil, it's the evil that every product that has to face, so thank you for sharing that. One of the things ... I was thinking about how this is the ultimate slow food, another big term that people are thinking about, one of the things that you mentioned earlier was the stem cell part. Can you talk a little bit about that, and why that's relevant? Because that's a term that has some negative connotations because people don't understand it, because of all the noise around it, but yet this is a game-changer in science, and this is a game-changer in helping us grown and thrive, it provides ... well, I'll let you go ahead and talk about it, please. Greg: Sure. Well, when we first started working on this it was a theory that one of our scientists came up with that some of these compounds actually increase the amount of stem cell activity in our body. At the time the medical community was just really started switching on to, "Hey, stem cells are important, everyone." The world, you're right, confused, I think there's still some confusion, but in general our stem cells in our body repair, and regenerate our entire body, and so this is how we ... Cells in your body regenerate and are replaced every so often depending on what kind of cell it is, and the way that that happens in our body are stem cells. Stem cells are called to a certain part of our body to repair from damage if you cut yourself stem cells come and repair that area. So there are certain messenger molecules that get sent out in your body to attract stem cells to the areas that are needed to repair or regenerate. Greg: What we found is that certain compounds within AFA, blue-green algae are actually, it increases the number of those messenger cells within our bodies, and if you're a science type, those messenger cells are called cytokines, and that then dramatically increases the movement of stem cells in your body. So what we found is that these compounds within AFA increase your own body's stem cells stimulation by 30%. So an increase of stem cells flowing throughout your body is a major breakthrough, and a really great thing for health, general health, and for regeneration. So we have ... Well, we have multiple double-blind placebo-controlled studies that we've done, as Tom mentioned science is one of the core tenets of our company, and we started doing that from the very beginning. So we proved out using a scientific method that this indeed generates more stem cell migration in our body and that that's a ... that has been shown scientifically in other studies in journals to be beneficial for overall health. Greg: So we created that product, we called it StemEnhance, and that's one of the products that consumers can get from Cerule. They sell that exclusively, and that's their big number one product, and they sell it throughout the world. So it's a phenomenal product, it really does work, anecdotally we've gotten so many people that have been helped around the world by that product, and it's really exciting. I don't go into anecdotal stories, I like to focus on the science, but I have to tell you there's a million in one story out there about what StemEnhance has done for people. So it's exciting to see, and then it also is a major immune boost product as well, so there's a huge immune property within StemEnhance as well, helping to boost people's immune system. Tom: Greg, one thing I wanted to elaborate on is, I'm not sure if this is what you were alluding to, but when you're talking about the stem cell products sometimes there could be some negative religious connotations that go along with that, and we have none, none whatsoever, [crosstalk 01:08:35] algae out of the lake, and that's what responsible for the additional migration of stem cells. So I would say it doesn't matter what side of either the isle or the debate that you happen to sit on, we sit dead center with not offending either one. We're just a healthy way of making your body kind of turbo-charge its [inaudible 01:08:59]. Greg: That's a great way to put it, Tom, and you're right, that's a good point. A lot of the early stem cells stuff was around questionable ethical stem cell harvesting techniques that we're being used by the pharma industry, and by scientists that caused a lot of people to be put off from anything having to do with stem cells. Well, we have nothing to do with that. Just like Tom said, we found natural compounds within algae that actually turbo-charges your body's stem cell response, which is a great way to put it. I like what Tom said. Dan: Well, thank you for the clarification, and thank you for sharing that because that's what this is all about, helping people understand what's really going on or what really matters, etc., and the notion that you guys are able to take plants, plant-based products which are regenerative, etc., I mean there's an abundance of them, and then enhance them to make it even better, and make it more available that's great. Thank you for coming on today, is there anything else that we haven't talked about that you want to share? Greg: I think the key thing for us is from a B2B to the standpoint with our algae there are select people that we work with. Our supply of algae is limited, in that we don't commercially harvest, it's wild harvest, so whatever Mother Nature gives us is what we have on a year to year basis. So we don't take on lots and lots of companies, but we still have room to be able to work with select customers that really understand, and get what it is we're doing and the benefits of our specialized rare algae products. So we're always looking for new customers, in that regard people that want to create innovative products with unique ingredients, and that's what we provide on the Desert Lake Technologies side. Then of course on the dryer side, we're always looking for new customers there, people that want to toll dry with us in our Southern Oregon facility, or even companies that are interested in investing and buying dryers. So anybody who [inaudible 01:11:33] check out our website at oregondrytech.com, or our algae site at desertlake.com, and we'll provide all those links for you. Dan, you can post in the notes. Dan: Great, I appreciate it. Thank you so much for coming on. I appreciate your time today, and thanks for making us all smarter. Thank you, and I look forward to our next conversation. Greg: Thanks so much, Dan. Tom: Thank you, Daniel. We're just a bunch of [inaudible 01:12:03] farmers out in Southern Oregon trying to make the world healthy. That's it. Dan: Out by four o'clock in the morning milking the cows, just kidding, what a visual. No, that's great. Tom: Exactly. Dan: Exactly, no, that's cool. Well, thank you again, I appreciate it. Tom: Thank you. Greg: We really appreciate it, thanks, Dan. Dan: Thanks. Kudos to you guys. Greg: Thank you. Richard: Yeah, thanks again for the opportunity, Dan, we really appreciate it. Tom: Thanks, Daniel. Dan: Have a great day. I appreciate it. Thanks for your time. Greg: You too, take care. Dan: Thanks, bye. Greg: Bye. Tom: Bye. Dan: I want to thank Greg, Tom, and Richard for coming on today, and for sharing their insights. I hope you find this episode inspiring, think about all the creative things that you could do if you had access to this kind of technology. Think about how you could improve a product, how you could disrupt the category, even more, that's what this show is about, giving the strategies, and the ideas to help you disrupt the way we think about food, even more, to help you differentiate your product against all the other products on the shelf, and help you stand out against any of your competitors. I'll be certain to put a link to Desert Lake Technologies, and Oregon Drytech on the Shownotes, and on the podcast page. Dan: This week's free downloadable guide that's sent to a new item checklist, the recipe for success, this is the foundation that you want to build your brand on. These are the foundational elements that you need to be thinking about as you grow and scale your brand, but more importantly, if you've got these foundational elements in place at the beginning then it's going to help you excel and grow it faster than it would otherwise. You can get that, as well as this week's Shownotes at brandsecretsandstrategies.com/session181. Thank you for listening, and I look forward to seeing you in the next episode. Oregon DryTech oregondrytech.com Desert Lakes Technologies desertlake.com Thanks again for joining us today. Make sure to stop over at brandsecretsandstrategies.com for the show notes along with more great brand building articles and resources. Check out my free course Turnkey Sales Story Strategies, your roadmap to success. You can find that on my website or at TurnkeySalesStoryStrategies.com/growsales. Please subscribe to the podcast, leave a review, and recommend it to your friends and colleagues. Sign up today on my website so you don’t miss out on actionable insights and strategic solutions to grow your brand and save you valuable time and money. I appreciate all the positive feedback. Keep your suggestions coming. Until next time, this is Dan Lohman with Brand Secrets and Strategies where the focus is on empowering brands and raising the bar. Enter your name and email address below and I'll send you periodic updates about the podcast. Sign up to receive email updates

Listen where you get your podcast

Like what you’ve heard? Please leave a review on iTunes

FREE Trade Promotion ROI Calculator:

Click Here To Maximize Sales And Profits

Free brand-building resources to help you grow and scale

Turnkey Sales Story Strategies FREE ON-DEMAND COURSE

Why Most Brands Fail – The Roadmap To Sales Success FREE ON-DEMAND COURSE

Essential In-Store Customers First Marketing Strategies FREE ON-DEMAND COURSE

How To Drive Profits With Sustainable Packaging FREE ON-DEMAND COURSE

The Retail Game – What You Need To Know With Bob Burke FREE ON-DEMAND COURSE

Sales Success Begins With A Solid Business Plan FREE ON-DEMAND COURSE

How To Turn Your OnLine Data Into Explosive Sales Growth FREE ON-DEMAND COURSE

2016 Category Management Handbook Page 20 & 21

Want A Competitive Edge? The Recipe For Success

New product innovation is the lifeblood of every brand. New products fuel sustainable growth, attract new shoppers and increase brand awareness. Know the critical steps to get your product on more retailer’s shelves and into the hands of more shoppers.

Empowering Brands | Raising The Bar

Ever wish you just had a roadmap? Well, now you do!

Don’t miss out on all of these FREE RESOURCES (strategic downloadable guides, podcast episodes, list of questions you need to be asking, and know the answers to, the weekly newsletter, articles, and tips of the week. You will also receive access to quick and easy online courses that teach you how to get your brand on the shelf, expand distribution, understand what retailers REALLY want, and address your most pressing challenges and questions.

All tools that you can use, AT NO CHARGE TO YOU, to save you valuable time and money and grow your sales today!

Image is the property of CMS4CPG LLC, distribution or reproduction is expressively prohibited.