Explore an effective Compostable Packaging Strategy to align your brand mission with sustainable packaging solutions*. This podcast episode discusses the concept of “earth digestible” print-on-demand packaging, highlighting its importance in the food industry and its potential to help brands differentiate themselves and increase profits. It emphasizes the challenges faced by emerging brands in accessing quality packaging and the impact of the traditional packaging supply chain on their agility and brand image.

Your brand's packaging needs to work hard and it should sell itself. Personalize your brand with your packaging. It should align with your mission and it should be compostable. Wouldn’t it be great if it could also help pay for itself? Learn how!

Packaging is a topic that is near and dear to my heart. This is one of the biggest pain points that most brands share with me.

You work really hard to create a product that's aligned with a great mission. Your packaging needs to align with that same mission.

In this podcast, you're going to hear Kelly talk about what he calls a fool's errand. What he means by this is that when you put a product, a package into a recycle bin, most often, it just ends up in the landfill. You're going to learn more about that in a little bit so stay tuned.

The reason that Kelly and I chose to do another podcast and another mini-course is to help answer many of the questions that we received at Expo West.

These are the specific pain points people shared with us that were not included in podcast episode 116, The Shocking Truth About Sustainable Packaging: Strategies to Save Time, Money, and Grow Sales. Basically, what all Expo West exhibitors and natural brands need to know.

I'll put a link to that podcast episode as well as the free mini-course that we've put together in the podcast show notes and on the podcast webpage.

The name of that free mini-course is “Earth Digestible Print On Demand Packaging Solutions.” You're going to want to check it out. In that course, we talk about what earth digestible packaging actually means as well as strategies that you can use to gain sustainable sales and compete more effectively in any category.

This podcast episode is a snippet of the new course that we just created, “The Secret Compostable Strategy Your Brand Needs to Know: Strategies to Grow Sales with Earth Digestible Printer Demand Packaging as a Profit Center.”

Yes, you heard me correct. A strategy to leverage your packaging as a PROFIT CENTER to help you get your product on more store shelves and into the hands of more shoppers. This is something that we discuss in depth in the free mini-course, over and above what's included in this podcast.

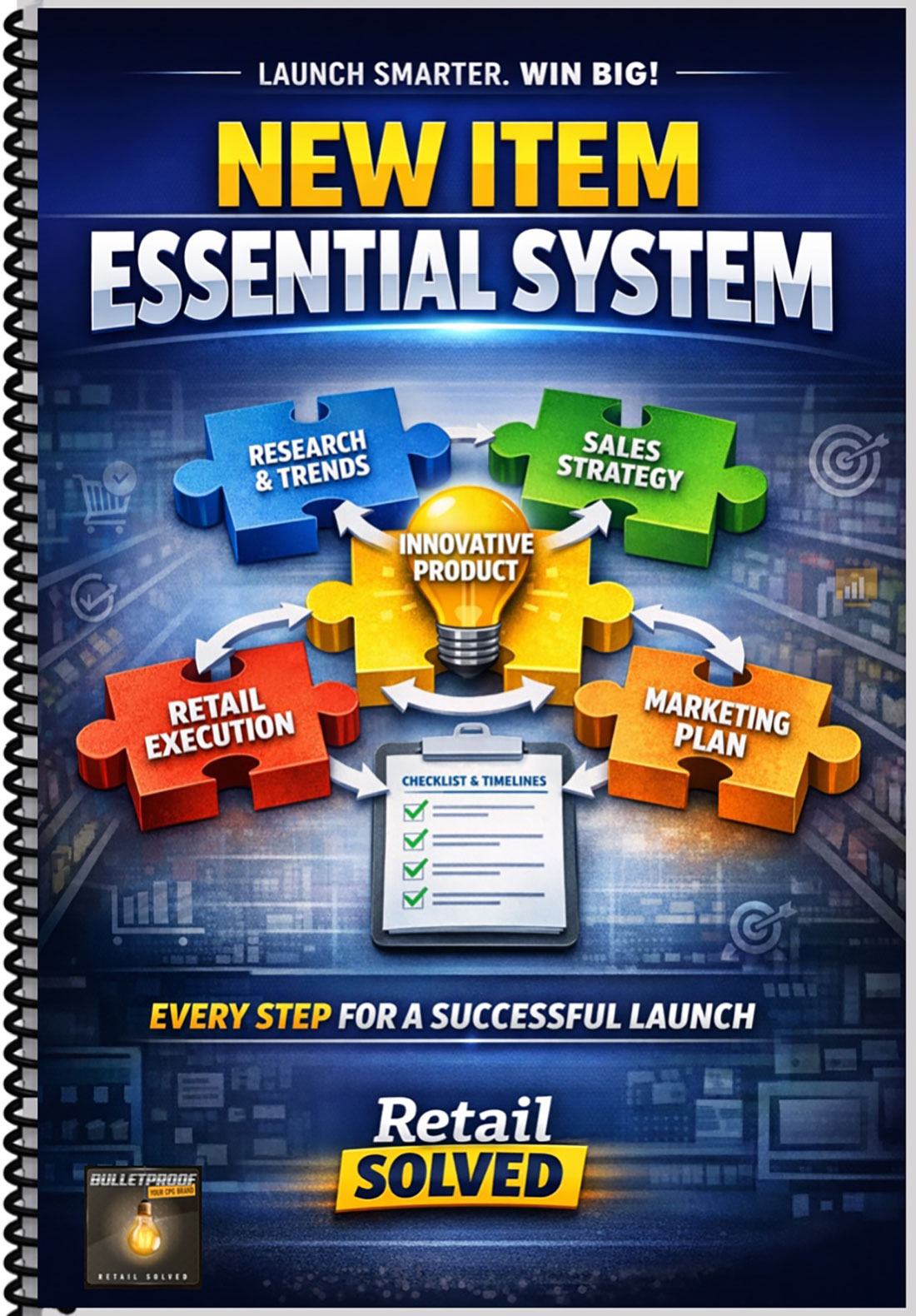

You will learn many helpful strategies including how to use your packaging to reduce your trade spending and maximize your trade marketing ROI, how to personalize each item, how to customize your packaging for a specific event, and how to turn your packaging into a profit center.

We also talk about what small brands need to be thinking about when they think about packaging. Spoiler alert. You're probably thinking about packaging in the wrong way and changing your thinking about packaging can help you compete more effectively to leverage this new technology to grow sales and differentiate your brand on a retailer's shelf.

Download the show notes below

Click here to learn more about NATUREFLEX™

Listen where you get your podcast

Important: Brand Secrets and Strategies has been rebranded to Retail Solved. Please swap all BrandSecretsandStrategies.com URL’s with RetailSolved.com. This is now the Bulletproof Your Brand podcast. Thank you for listening! BRAND SECRETS AND STRATEGIES PODCAST #128 Hello and thank you for joining us today. This is the Brand Secrets and Strategies Podcast #128 Welcome to the Brand Secrets and Strategies podcast where the focus is on empowering brands and raising the bar. I’m your host Dan Lohman. This weekly show is dedicated to getting your brand on the shelf and keeping it there. Get ready to learn actionable insights and strategic solutions to grow your brand and save you valuable time and money. LETS ROLL UP OUR SLEEVES AND GET STARTED! Dan: Welcome and thank you for tuning in today. Packaging is a topic that is near and dear to my heart. This is one of the biggest pain points that most brands share with me. You work really hard to create a product that's aligned with a great mission. Your packaging needs to align with that same mission. In this podcast, you're going to hear Kelly talk about what he calls a fool's errand. What he means by this is that when you put a product, a package into a recycle bin, most often, it just ends up in the landfill. You're going to learn more about that in a little bit so stay tuned. The reason that Kelly and I chose to do another podcast and another mini course is to help answer many of the questions that we received at Expo West. These are the specific pain points people shared with us that were not included in podcast episode 116, The Shocking Truth About Sustainable Packaging: Strategies to Save Time, Money, and Grow Sales. Basically, what all Expo West exhibitors and natural brands need to know. I'll put a link to that podcast episode as well as the free mini course that we've put together in the podcast show notes and on the podcast webpage. The name of that free mini course is "Earth Digestible Print On Demand Packaging Solutions." You're going to want to check it out. In that course we talk about what earth digestible packaging actually means as well as strategies that you can use to gain sustainable sales and compete more effectively in any category. This podcast episode is a snippet of the new course that we just created, "The Secret Compostable Strategy Your Brand Needs to Know: Strategies to Grow Sales with Earth Digestible Printer Demand Packaging as a Profit Center." Yes, you heard me correct. A strategy to leverage your packaging as a PROFIT CENTER to help you get your product on more store shelves and into the hands of more shoppers. This is something that we discuss in depth in the free mini course, over and above what's included in this podcast. You will learn many helpful strategies including how to use your packaging to reduce your trade spending and maximize your trade marketing ROI, how to personalize each item, how to customize your packaging for a specific event, and how to turn your packaging into a profit center. We also talk about what small brands need to be thinking about when they think about packaging. Spoiler alert. You're probably thinking about packaging in the wrong way and changing your thinking about packaging can help you compete more effectively to leverage this new technology to grow sales and differentiate your brand on a retailer's shelf. Before I go any further, I want to leave a quick shout out to a listener that left a review. "This is next level," says Tasha O., "Great information on leveling brand recognition, marketing, and effective ways discussed on how to apply this knowledge." Thanks, Tasha. I really appreciate the review. If you want me to share your review, please send me an email, leave a review on iTunes, or comment our LinkedIn, Instagram, or Facebook. I also want to remind you that at the end of every episode, there's one free downloadable guide that you can use to add rocket fuel to your brand. I always include quick-to-digest strategy that you can instantly adopt to make your own. One that you can use to grow sustainable sales and compete more effectively. Remember, the goal here is to get your product on more store shelves and into the hands of more shoppers. Now, here's Kelly Williams with NatureFlex. Kelly, thanks for coming on today and for talking to us about sustainable, compostable packaging. Can you first start by telling us a little bit about yourself and your journey a NatureFlex? Kelly: Will so. As you said, Kelly Williams, I've been in the packaging industry for, well, almost 25 years. Chemical engineer by training and I ended up starting out in this industry right when these big companies were merging together. ExxonMobile and these big companies are all coming together. A lot of things really changed at that point and up until about 2006, I always wondered to myself when's it going to slow down? We just kept adding more plants and more plastic and it was all about more, more, more. I'm thinking there's got to be a point. I'm on that side developing these incredible film materials. Plastics that go into the films to make up your- food last on a shelf. I'm there designing what I think is the best thing for the planet not realizing where we're at today. From there, I kind of got into other technologies and then I got into digital printing which I'd like to talk a little bit about and that kind of lead me to where I am not which is with Futumura, the NatureFlex films, which are naturally biodegradable, compostable, marine degradable films used in flexible packaging. What lead me here is based on emerging brands that are asking about it. They want it and there's just a lot going on right now between the choices that a brand has to make in terms of do I go recycling or do I compostable or do I just continue to down gauge what I'm currently using? There's just a lot going on involving packaging. In fact, it's interesting because at this years Expo West versus last years Natural Products Expo West, last year, for the first time ever, packaging became this cornerstone conversation. It's not a tertiary conversation that other people in the company have with suppliers. It's at the top to where, this year, I'm not even sure there was another conversation. It was all about packaging. Which is pretty exciting. But also it tells to the reality of the situation. Dan: Thanks, Kelly, for sharing that. One of the reasons why we're having this conversation is a follow up to the mini course that we already did about earth digestible print-on-demand packaging. To your point, at Expo West, there were a lot of questions about sustainability and compostability. What does that mean? That's why we decided to have this second conversation to try to clear that up and try to answer many of the questions that people were asking at Expo West. So thank you for coming on today. One of the things that's great about this relationship that you and I have formed is that I help brands get their products on more retailers shelves and the hands of more shoppers by teaching them the advanced strategies to level the playing field between them and the big companies. You have the unique opportunity to bring in that part about the packaging because the packaging is your brand. And, so, being an expert in that area, bringing that piece to our conversation makes so much sense. Even better yet, the fact that you can talk about something that is pretty revolutionary in terms of the way we look at the category right now. Earth digestible print-on-demand packaging. First of all, let's talk about what is sustainability? How would you define it and what do brands need to know or understand about sustainability so that we can frame this conversation? Kelly: Yes. Sustainability, in a lot of ways, is almost a vague term because everybody has a different understanding of it. Unfortunately, for some, I think sustainability means managing downstream liability and, for others, it is doing the right thing from a genuine perspective but not sure what that is. You're seeing a lot of people genuinely trying to understand and they're getting misinformation, maybe getting bad information, they're being convinced that this is the right thing to do and I'm going to try to convince you that I feel like I have the right way. But, again, do your homework. It's kind of a really dynamic- I think in the beginning, brands really didn't know even who to put into those positions. Right? Sustainability. Now there's people who really do have experience in that field that they're bringing in. It's a very dynamic space. But, to me, sustainability means what do we need to do immediately today to even think about sustaining nine billion people? I talk about packaging in general which we all know single use packaging is a big issue but I tend to focus on the flexible packaging which is the most important because it's been growing at a phenomenal rate for a very good reason. It's ubiquitous in society for a very good reason. You cannot feed nine billion people without it. When it first started to take over from rigid packaging, there were these great benefits. It's thinner, it's lighter, you can produce it in Germany and send it to the U.S. It allowed so much flexibility. You can change it very readily. But the one thing that we all knew on the other side of that, it was this big dark secret that no one talked about, is you can't do anything with it after it's been used. After that product's been consumed, there's nothing you can do with it. We knew that and from a flexible packaging perspective, if we continue to put products into packaging that ultimately harm the very soil for which you grow the food that you processed to put in that package or that you feed the animals that you then processed to put in that package, you kind of eliminate the need for the package. Packaging waste is a very serious problem and what's happened in the last 10 years alone, we've produced as much plastic as the entire previous century. The rate of production is no where near slowing down. What you realize is the flexible packaging industry has become so efficient and so incredibly over engineered that you can literally package a bag of chips that, even under some light, will go rancid in a very short period of time. We could put chips in a bag that you can eat 12 months from now and they're fine. That incredible over engineered, cheap, efficient system is akin to other things we've seen in history where when verticals get that efficient and the world around it changes, the only way for innovation to happen is for it to break. It has to break for those innovations to happen and we really are truly in that right now. We're seeing it. We've been seeing it playing out for about eight years because we make one of the key films that replace- Just about every flexible package, there's a role that our film plays in it because of its heat resistance, it's stiff, and all those mechanical properties. But that's already happening and it's coming from emerging brands. Emerging brands have created a tsunami against the legacy brands to the point that they can't buy them any faster. As they buy them, it actually adds more complexity to their already chaos and it's never going to stop. Walking around shows like Expo West, it's like you're watching an industry in deregulation. Anyone can become a brand. All you need is a decent product, a great story, a catchy name, and you're in business because you don't have to go to the store shelf to grow your brand. Legacy brands are protecting the shelf space and the end caps where the battle is being held elsewhere. I think that these brands represent the future of the food industry, quite frankly. What they don't know, as they're trying to figure out how to do the right thing, is they're not getting the information that they need. That just seems to be pretty loud and clear that they're really trying to understand what should I do? Because they genuinely do worry. Every time they buy another two million bags of polypropylene that they know will outlive their great-great-grandchildren, that worries them. I think part of what we can do here, Daniel, is to kind of weave together the things that you and I both do and show a coherent way to rethink the way a product goes to market. Dan: Thanks for sharing that. Let me unpack that. There was a lot there. First of all, sustainability. Most of these small brands, most people think that when you put something in the recycle bin, automatically, it gets recycled and gets reused. That's not true. We were going to talk about that a little bit. So we'll dig into a little bit more later. But the point is and what you're saying, and I really appreciate you getting into this, is that that's not true. There really isn't a lot of good solutions. At least there wasn't a lot of good solutions in terms of packaging. You use something one time, you throw it away and it ends up in a landfill. So let's back up a little bit and let's start breaking this down. You made the comment that emerging brands are the ones that are changing the industry. The ones that are leading this charge. When you're talking about emerging brands, one of the things that I think about are the small disruptive brands that you talked about that are able to come up with a product pretty much in their kitchen or something like that and get it on the shelf pretty quickly. But the reality is is that it takes a lot of time to buy the film, to get the film shipped here, to get it printed, etcetera. Let's first talk about what do things look like today? If you're a brand and you've come up with a product and everyone including your mom loves it, how long does it take you to get that product onto a retailer shelf and what I'm really getting at is what's involved in getting that product into a package and then getting that package to market? Kelly: Perfect question because that's really part of how the emerging brands are kind of chipping away at the foundation of the existing system. The way packaging is made and I'll show you an example here. So this would be an example of a flexible package. It's a pouch. You generally have this plastic film that you print the image. So when you're looking at it, the ink is actually on the back side of that film and then you glue it together with adhesives to all the other materials to create this final package. That takes time. Right? It tends to be wasteful in the way. Each of those steps. But the thing is, it always starts with printing. The first thing you do is print versus pre-making the package and then just surface imaging it, protecting it and getting it out. That never happen because when the plastics industry brought flexible packaging to the CPGs, those types of overprint protective coatings just didn't exist. They do today. In fact, it's happening more and more. It's just nobody talks about it. Going to that model. But when you think about it from a brand's perspective, they're all outsourcing. They're outsourcing packaging, they're outsourcing a lot of the actual product manufacturing, they're outsourcing marketing, they're outsourcing creative design. They're really focused on retail relationships and making sure they dominate that shelf space. By the time they go through hundreds of ideas to come up with the few that they go to market with or to go to the next step, which is actually prototyping where somebody will make you 50 or 5,000 of these that you take to a show or some way to figure out what product am I taking to market? You go through all that process. By the time you get to the point that you're ready to execute, you're looking at another three to four months to even get it into a package because of how long it takes to get the packaging, to figure out that everything has been vetted. Can I put the new non-GMO icon on it? All the stuff with labeling alone just continues to extend that amount of time. The bigger the brand, the more so this is true. It'll take you a year to launch one new product per category because of how much effort it takes to do that. With e-commerce and other channels, that could be faster but that packaging piece is still. You finally get that opportunity as a new brand to put your product, let's say, on Whole Foods' shelf in 13 states. If they need it next month, you're not going to be able to do it because it just takes too long to get the packaging. Dan: Let's talk about that a little bit more because you're absolutely right. One of the things I think people don't understand and, again, this is why we're having this conversation is that if you want to put a product- If you're a small brand, and when I say small brand, basically, anything smaller than a P&G, a Frito or something like that in terms of your packaging needs. Okay? So if you are a smaller brand and you need 10,000 units of packaging, that is a small order that most packaging companies in the U.S. don't have time for, don't have the capability to take care of. When you're talking about that packaging, you shared with me several times that someone needs to go over to Asia to buy the film to have it shipped over here. Well, that takes time. As you mentioned, the shipping cost, buying the product and having all of the printing and stuff done and then, to your point, you get another label, another certification, etcetera. That elongates the process. Yeah. You've got the product, you've put it in a bag and now you're ready to put it on a shelf but, like I said, you've got another certification or something you want to put on it. You found a mistake in your packaging and you need to pivot. You need to change. That takes time. If I were to come to you if you were the packaging person and I ask to put my product in a package, how long would it take for you to order the packaging, get the printing done and everything else for one SKU just to get one product on a retailer shelf? Without any other changes in the process. Kelly: You're absolutely right because the manufacturers of flexible packaging have also been getting bigger just like the CPGs. They have resources. For decades CPGs have not necessarily invested in human resources with expertise in packaging. They really just rely on their suppliers to do it. Well, as the suppliers get smaller in numbers, they're not exactly expanding the number of people they have. The legacy brands tend to kind of dominate those relationships. As a young brand coming in saying, "Hey, I need packaging." First of all, they're not going to get the attention. Second of all, no one's going to make five SKUs by 15,000 stand up pouches. So they're forced to go to Asia to get it because they're willing to do it but it doesn't come any faster. That's why when you go around anywhere, you see so many new either shop owned product line or you see a lot of the emerging emerging in what? On printed bags and pouches with a label on it. If you walk around the natural organic retailers, you will find pouches and bags that had been over labeled because by the time they got the packaging, something changed. Now, it's quicker just to spend the money to put a label over top of the label than to order new packaging. Dan: The reason this matters is because your brand is everything and you want to make a good impression on the retailer shelf. You can't afford to get this wrong. If you've got a product that looks like you actually belong in a county fair as opposed on a retailer shelf, that can hurt your sales. When we're talking about packaging and what it takes to get the product into a package. We've already talked about how long it takes to get it ordered and get it onto a retailer shelf. Emerging brands are changing the way that people think about packaging. One of the things that you and I have talked a lot about is that emerging brands are typically mission driven. Now, one of the things that I've shared with your or that we've had a lot of conversations about is that I teach brands how to leverage the mission around their package, around their product, with retailers to help them drive traffic in stores. The challenge with that is that you take all your love, all the effort, everything that you've got, you put it into your package and you're really proud of it and you've got a great mission behind it. And then you put it on a retailer shelf but, yet, your packaging doesn't align with the mission that your brand represents or stands for. As I mentioned, what I do is I try to teach brands how to leverage that mission at shelf. What's unique about this relationship between you and I and what NatureFlex does is now, all of a sudden, your mission can be your packaging because consumers want products that they know, like, and trust. They want to know that when they go to recycle a product that their product is actually going to be recycled. To go one step further, earth digestible, we'll get to that in a minute. Why does that matter from your perspective? What have you seen in the industry from the big brands to the small brands? How do you see this playing into the way consumers look at products today? Kelly: Ultimately, consumers are driving it. We all know that. When I look at the way food gets made and packaging gets made and they come together into that unit on the shelf, that structural supply chain is grossly incongruent with a consumer driven value chain that wants authenticity. They want it faster. It's not the time value of money it's the money value of time. You have this great product that people are really starting to resonate around. Let's add to that your social purpose. Your mission makes them want your product even more. But you have to deliver it. What the larger brands that become so- It's probably fair to say somewhat paralyzed by that relationship they have with retailers because that battlefield that they're trying to product, they have another- retail premium private label brand that wants that shelf space too. So they're fighting this battle here without realizing how all these little fish are schooling together to really put a lot of pressure on a foundation. What they don't realize is they can really break the foundation wide open because no one has realized that packaging should never be considered a cost center. It should be considered a profit center because we spend far more time interfacing with packaging on a daily basis than we watch TV commercials, listen to radio ads, you're sitting there waiting with your clicker, for that first second, you can get past that ad on YouTube to watch something. But we look at this. This is the way that you can communicate with your consumers. But, today, you don't know who bought it. You have no relationship with that consumer once it leaves your co-packing operation. With new technology, you can actually now engage in that relationship. You can not worry about the things that need to change. You can regionally personalize. You can co-brand. There's things that you can do that you never could do before. If you are a mission based organization, even better. Let's say you actually have converted yourself to a B Corp which was first made possible by the state of Maryland in 2010. I think now 30-something states offer it and since 2010, we've had seven times more ethical claims on packaging than before. I think it's the greatest thing to happen to American business is to be able to set yourself up as a B Corp. Because by being a benefit corporation, Daniel, what you have is you have to have clearly stated social purpose goals that you're measured against. But what it allows you do is to use some of your profits to fuel that. No matter who decides to own you, they can't prevent you from doing that. So it creates protection from greed, quite frankly, and consumers resonate with that. They don't want to hear your five year old story. They're already giving you credit for that. They want to live as part of a journey with you. As part of that journey as part of all the great things you're doing in Guatemala or South Africa, all those things, they want to be a part of it. They want to be invited into designing the next package, the next product. Today, we're so hung up on cost that we're not thinking about the logical aspect that everything starts and ends with that package. Everything you've done to this point, this is the unitization of it. We should have every single package uniquely scannable so you can direct to the consumer. If there's ever a problem, let's say, you get a glass shard in some cereal, you can isolate that event instantly because of the track and traceability of that versus pulling billions of dollars out of the supply chain every year because you just don't know where the event happened. It's a lot of money that goes into recalls. They do mock recalls in the industry just to practice what to do if a recall needs to happen. But if you're managing the supply chain at that unit level, you can now manage that. Right? It's funny because the pharmaceutical industry has been doing this. It's 100% track and trace. It's because all of the pills, everything, is co-packaged at a point where it gets labeled. Every label. So they're able to control that. As the food industry is moving more forwards that same model where they're outsourcing that, it becomes logical that you can start tying these things together that aren't new concepts. They've just never been applied to an industry that's blinded with chaos and only looks at packaging as a cost center. Today, Daniel, we have over a million combinations of materials to make up flexible packaging when there really only needs to be a dozen, two dozen max. Dan: Sounds overly complicated which I understand. Thanks to you, I've had the privilege of really digging into this and understanding what's involved in a flexible package. It can be pretty complicated and it can be something that not only is it really dry but you pretty much have to have a PhD to really get through it if you're not part of that environment. For you to come on, thank you, and make this simple is so simple and, again, that's why we're doing this. When we're talking about the ability to have flexible labels and flexible packaging and being able to change it and make that package, let's call it, dynamic. One of the benefits of that is you want customers to know I can trust your product. Well, nowadays, the technology exists where you can identify who planted the seed, where it was planted, how it was taken care, how it was harvested, and how it ends up in the product. The point is that with the ability to do that, that creates a unique relationship between you and your end consumer. That allows you to have a conversation with your consumer in terms of you've made a commitment to your consumer saying, "This is what we're doing. This is what our product is about." But now you can demonstrate it. Now you can prove it. You could actually put a snowflake or a barcode on your packaging that helps the consumer go back to your website or something where you can trace back to the ingredients. On that note, kind of jumping around a little bit in terms of the way we were talking about this, let's talk about print-on-demand packaging. The reason that's important- A couple reasons. Your brand, you're ready to go, you've got your product ready, but you've got to get the packaging done. A minute ago, we were talking about how it takes sometimes four to six months or longer to get that packaging on the shelf. But you've already secured the investment to be able to do that. Now, your VC company or whoever's loaning you the money, they want a return on their investment. But you can't put a product on the shelf until you get the packaging. So print-on-demand allows you to shorten that cycle to almost literally get the product on shelf almost instantaneously. We'll talk about that in a second. But, now, let's overlay that with the ability to customize the packaging and make it unique to the region, as you said, or to the product or to whatever else. How does that fit into the industry and how do you see that changing the way brands can go to market? One more question, how do you feel brands can leverage that to differentiate themselves from the big brands? I'm sorry. Go ahead. Kelly: No, no. That's actually a great next part of kind of unwrapping this thing. You buy a bag of tortilla chips from a major brand that has a lot of real estate on the shelf. Chances are, that bag was filled within the last seven, 14, 21 days but the packaging was made nine months ago. That's unsustainable as well. But that's the way it's designed. It's designed to put a tank around chips to handle that journey. That's not the journey of tomorrow. That journey is about reacting quickly to what people want. You don't ship packaging to one giant plant that services the entirety of North America. You don't ship all of that packaging on a truck to all these different places that are putting their product in the package. You got to think about the old big plant manufacturing to now the mobilization of the capacity you need to do the things you need to do. This is a conversation among major brands about rethinking the virtual economy and how you take advantage of it. Well, packaging is no different. With digital printing, you can set up a digital printing operation anywhere. You can put it behind glass in a strip mall and be making flexible packaging. By removing the complexity of the way it's always been done- Peter Drucker always said to do something new, you had to stop doing something old. If you start applying digital printing to the old way of doing things, you're really not doing anything new other than putting the Green Bay Packers on a bag of chips. Which is great. I love the Green Bay Packers. My wife's from Wisconsin. But that's not- Dan: I won't hold that against you. Kelly: But that's not what digital is about. Digital is about managing the supply chain at the unit level. We have to realize that we're approaching a point to where nothing will ever be printed the same way twice. The ability for a legacy brand to predict that every week they're going to sell four million berry flavored granola bars in the Greater Atlanta Area, those days are numbered. That predictability will not be there because it's about what consumers want. All these things are going to kind of come together. But what I love about it is how these emerging brands are creating their identity through e-commerce channels. Starting to find some way in and leverage that. They're doing it from the beginning so they understand it. When you think about that, the packaging design is different. You're more open to the size. If I'm a printer and I'm providing these brands flexible packaging and I said, "Look, I can't make every size that you want. But I can give you this menu of sizes and one of them is going to work for you. But you can change what you print on it anytime you want. You can have 50,000 bar wraps on a roll to where every single one of these is different. Whether it's just that it scans, uniquely scannable, or the actual artwork changes." You can now do those things. By doing that, you're creating a whole new context of what you have to deliver and compete with. Does that make sense? Dan: Sure. Yeah. No, I get it. Let me try to frame this a little bit differently. Not only is that important as a big brand as one of the challenges, their- Let's call it their achilles heel. That's the way they go to market because that's the way they know to go to market because that's the way they've been going to market. These small disruptive brands are changing the way people think about food. One of the things that I love about these small disruptive emerging brands is that they're doing things that no one else has thought of. They're thinking about of the box. Let's go one step further. Snacking occasions. In terms of meal occasions, people don't eat three squares a day. They eat a lot of snacks. If you're an emerging brand and if you've got your product in a snack pouch or a snack something, snack wrapper, and you can change and differentiate that and get it into different shelves, different markets, quickly, then it allows you to execute more efficiently. As you become more efficient in your ability to execute and get that product in a store shelf, it allows you to start earning revenue right away so you can start growing and paying back your investors and so on and so forth. The reason this is so critically important is it gives small emerging brands a unique and sustainable competitive advantage. Instead of waiting, like you were saying, where you're a chip company. You've got packaging that you ordered nine months ago. Before you can put that on a retailer shelf, well, okay, that's fine if you've been in business for a while. But if you haven't been in a business for a while or you've got a new label- Let's say, you're going along and everything's fine and all of sudden you get a non-GMO certification, like you said, well, wait a minute. You want to be able to celebrate that on your packaging but that means a complete packaging redesign so you've got to kind of start from the ground up almost to redesign it. Or you could just use print-on-demand packaging. The benefit of this to the consumer is that you can get the product in the hands of the consumer a lot faster and, more importantly, if you can use this technology to align your product with your brand messaging then you can invite younger shoppers and shoppers who are really interested in supporting those missions to buy your brand. So, again, Kelly, thank you so much for coming on. Anything else? Kelly: No. No. That was great. Thank you, Daniel. Dan: Cool. Kelly: Always great - talking to you. Dan: I want to thank Kelly for coming on today and for sharing his wisdom and his insights and for helping make this very complicated topic simple and easy to understand. I also want to remind you that this podcast is a snippet of our free mini course, The Secret Compostable Packaging Strategy Your Brand Needs to Know. I'll put a link to it in today's podcast show notes and on this episode's webpage. This week's free downloadable guide is The Essential New Item Checklist - The Recipe for Success. In this free downloadable guide, I cover the key things that you need to have in place to be able to build a healthy foundation for your brand. The recipe to help you get your brand on more store shelves and into the hands of more shoppers. You can get that instantly by going to the podcast webpage which is brandsecretsandstrategies.com/session128. Thank you for listening and I look forward to seeing you in the next episode. NatureFlex (Futamura) http://www.futamuragroup.com http://www.futamuragroup.com/divisions/cellulose-films/products/natureflex/ This episode's FREE downloadable guide New product innovation is the lifeblood of every brand. New products fuel sustainable growth, attracts new shoppers, and increases brand awareness. Know the critical steps to get your product on more retailer’s shelves and into the hands of more shoppers. CLICK HERE TO DOWNLOAD YOUR FREE STRATEGIC GUIDE: The Essential New Item Checklist - The Recipe For Success Thanks again for joining us today. Make sure to stop over at brandsecretsandstrategies.com for the show notes along with more great brand building articles and resources. Check out my free course Turnkey Sales Story Strategies, your roadmap to success. You can find that on my website or at TurnkeySalesStoryStrategies.com/growsales. Please subscribe to the podcast, leave a review, and recommend it to your friends and colleagues. Sign up today on my website so you don’t miss out on actionable insights and strategic solutions to grow your brand and save you valuable time and money. I appreciate all the positive feedback. Keep your suggestions coming. Until next time, this is Dan Lohman with Brand Secrets and Strategies where the focus is on empowering brands and raising the bar.

Enter your name and email address below and I'll send you periodic brand building advice, tips and strategies.

Sign up to receive email updates

FREE Trade Promotion ROI Calculator:

Click Here To Maximize Sales And Profits

Image is the property of CMS4CPG LLC, distribution or reproduction is expressively prohibited.