Your packaging is the first impression that shoppers have of your brand. Is your packaging sustainable and does your messaging and mission resonate with shoppers?

You've put your blood, sweat and tears and everything you've got into making a product that's going to revolutionize the category. A product that's going to put your brand on the map, that's going to change the way people think about healthy, nutritious food. You spare no expense and you go out of your way to find the best clean label ingredients because nothing's too good for your customers. You want to make sure that they know, like and trust your brand, and that they know that when they buy your brand, they're buying the absolute best products available anywhere. You've worked hard to develop a mission that's going to resonate with your consumer.

And now all you have to do is get your product onto a retail shelf. It doesn't matter whether you sell your products online or in traditional retail. This is something that every brand needs to think about. But before you can do that, you've got to put it in a package. You need something that's flexible, that offers consumers the convenience that they want so that they can share and enjoy your product where they want when they want. So now you begin to look high and low for packaging that's sustainable, that aligns with your brand's mission.

And now the problem. There aren't a lot of great solutions out there. You want a package that's recyclable because you don't want to contribute to the landfill. Okay, now for the bad news. This episode is about the shocking truth about sustainable packaging. The sad reality is that most recyclable packaging ends up in the landfill anyhow. But there's a better way. This podcast is about packaging solutions and strategies to save you time, money and the insider secrets to get your brand on the shelf. Packaging is one of the most critical aspects of every brand's success.

Let's face it, your packaging is a representation of your brand. It physically has your name on it. It's the first impression that customers have about your product. Make sure it's a good one. Your packaging is also a representation of your brand, and your commitment to your values and your mission. Every brand that I work with struggles with this. That's why I brought in an expert, a good friend of mine, Kelly Williams of Futamura. This can be an extremely complicated topic, but Kelly has a unique way of making it simple and easy to understand. These are the things that you need to know. These are the things that you need to be thinking about as you figure out how you take your product from the kitchen, get it onto a retailer's shelf, and then into the hands of the shoppers that buy your product.

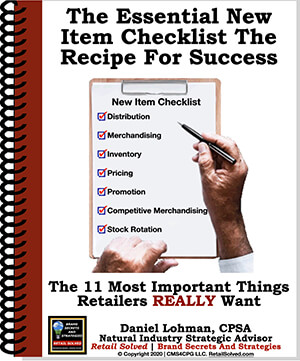

Before I go any further, I want to remind you that there's a free, downloadable guide for you at the end of every podcast episode. I always try to include one easy-to-download, quick-to-digest strategy that you can instantly adopt and make your own. One that you can use to grow sustainable sales and compete more effectively. Remember, the goal here is to help you get your products onto more retailer's shelves and into the hands of more shoppers. If you like the podcast, share it with a friend, subscribe, and leave a review.

Now here's Kelly Williams.

Download the show notes below

Click here to learn more about Futamura

BRAND SECRETS AND STRATEGIES PODCAST #116 Hello and thank you for joining us today. This is the Brand Secrets and Strategies Podcast #116 Welcome to the Brand Secrets and Strategies podcast where the focus is on empowering brands and raising the bar. I’m your host Dan Lohman. This weekly show is dedicated to getting your brand on the shelf and keeping it there. Get ready to learn actionable insights and strategic solutions to grow your brand and save you valuable time and money. LETS ROLL UP OUR SLEEVES AND GET STARTED! Dan: Welcome. You've put your blood, sweat and tears and everything you've got into making a product that's going to revolutionize the category. A product that's going to put your brand on the map, that's going to change the way people think about healthy, nutritious food. You spare no expense and you go out of your way to find the best clean label ingredients, because nothing's too good for your customers. You want to make sure that they know, like and trust your brand, and that they know that when they buy your brand, they're buying the absolute best products available anywhere. You've worked hard to develop a mission that's going to resonate with every consumer. And now all you have to do is get your product onto a retail shelf. It doesn't matter whether you sell your products online or in traditional retail. This is something that every brand needs to think about. But before you can do that, you've got to put it in a package. You need something that's flexible, that offers consumers the convenience that they want so that they can share and enjoy your product where they want, when they want. So now you begin to look high and low for packaging that's sustainable, that aligns with your mission, your brand mission. And now the problem. There aren't a lot of great solutions out there. You want a package that's recyclable, because you don't want to contribute to the landfill. Okay, now for the bad news. This episode is about the shocking truth about sustainable packaging. The sad reality is that most recyclable packaging ends up in the landfill anyhow. But there's a better way. This podcast is about packaging solutions and strategies to save you time, money and the insider secrets to get your brand on the shelf. Packaging is one of the most critical aspects of every brand's success. Let's face it, your packaging is a representation of your brand. It physically has your name on it. It's the first impression that customers make about your product. Make sure it's a good one. Your packaging is also a representation of your brand, and your commitment to your values and your mission. Every brand that I work with struggles on this exact topic, and that's why I brought an expert, a good friend of mine, Kelly Williams of Futamura. This can be an extremely complicated topic, but Kelly has a unique way of making it simple and easy to understand. These are the things that you need to know. These are the things that you need to be thinking about as you work to figure out how you take your product from the kitchen, get it onto a retailer's shelf, and then into the hands of the shoppers that buy your product. Before I go any further, I want to remind you that there's a free, downloadable guide for you at the end of every podcast episode. I always try to include one easy-to-download, quick-to-digest strategy that you can instantly adopt and make your own. One that you can use to grow sustainable sales and compete more effectively. Remember, the goal here is to help you get your products onto more retailers shelves and into the hands of more shoppers. If you like the podcast, share it with a friend, subscribe, and leave a review. Now here's Kelly Williams. Kelly, thank you for coming on today. You were on podcast episode #9 and I'm so thrilled that you're here again today. We have something exciting to share with everyone. But before we get started, can you begin by telling us about yourself and your journey to where you're at today? Kelly: Absolutely, Daniel, thank you. So Kelly Williams, I've been in the flexible packaging industry for I guess now almost 25 years. Started out in the plastics industry working with the companies that make the films that go into most of the packaging that you have when you buy it at the store. My path took me to a lot of different places along that supply chain, even down into adhesives and coatings that are used and into digital printing, which is a new technology that is already starting to show its potential in changing the way things are done to now ... so when I left the plastics industry they were just now started to talk about bio polymers and compostable packaging materials. All of that conversation was going on at the same time. The label printers were going to start making flexible packaging and stand up pouches. So the industry was going to see a billion stand up pouches in the near term, and now way, way past that. So all of those conversations were going on that are all relevant today. And so where I'm at now is with Futamura, and Futamura acquired the cellophane assets, the original DuPont cellophane plants. That was actually technology invented in the early 1900's, which is essentially transparent paper. So this was the first transparent packaging film used to package food and consumer products, largely replaced by polypropylene in the late 70's into the early 80's. But what was interesting about that material is it's natural compostable, marine degradable, microorganisms will consume it. So we're kind of seeing that tide shifting back. So I ended up going to this company to help serve them in terms of aligning what I consider the future of flexible packaging manufacturing with a revised, you know like a new value chain that is causing pressure in the current supply chain for how packaging is manufactured. And when you line all those pieces up, you realize that you can actually get the better package to the market, to the store shelf, without worrying about it being a higher cost. There's elements of that equation that they kind of brought me in to navigate. Dan: Appreciate you going through that. And of course, the reason that we met is because you reached out to me first, and I appreciate you doing that. And one of the things that I'm passionate about, one of the things that I'm really focused on is helping healthy brands get their products to more retailer shelves and in the hands of more shoppers. Well, let's frame the conversation. You put a lot of effort and energy into building a mission around your brand, to cleaning up the ingredients, to giving consumers what they want. But then you put that product in a package that ultimately ends up in the trash. Even if it says it's recyclable, it ultimately ends up in the trash in most situations. And what I love about what you have, your passion, your enthusiasm around that is that you've got a technology and a strategy to help brands get their products to market quicker in a package that aligns with their mission, a product that as you said, if it doesn't blow away ... what's the term you used again? Kelly: If it can blow away, it needs to go away. And safely. Dan: Thank you. Exactly, so being able to align that with your mission, so now what your package is made of is every bit as important as what's inside the package. Because consumers want healthy products. That's a given. We've already talked about that a lot on the podcast, etc. Now you can align your mission around the packaging itself and how more importantly, you can help leverage that capability, that package, with the retailer, with the consumer, to help drive more sales to your product. But more importantly, giving customers what they really want. Kelly: When you and I met, we kind of joked that we kind of have two sides of the fence, right? So I've been on the upstream side of a very important fence, and you're on the downstream side. You're focused on helping emerging brands that want to put healthy products into the market, and you want to help them be successful navigating that category space and that retail space. And I'm looking at it saying I can help them do that through the packaging. And when we work together, I think it's pretty powerful. Because it is all about packaging, execution, quality of the product. Because these are brands that really don't know a lot about packaging. And they don't want to know. That's really not where their heart is. But we can show them a way to do things that no one else has ever done that could really make the difference. And it's so exciting just to see this. It's almost like today, anybody can become a brand and it's really exciting to see. And I know deep down, whether a B Corp or not, there's a passion for making sure that they put their product in something that's safe. And I think together we can really help them get there. Dan: Absolutely. And thank you for sharing that. And the point being that if you're going to have a mission or align your product with something, better quality food, whether you're giving back to a third world country, whether you're helping out at home or whatever, having your package align with that mission, and having your package, your package itself, be a part of your mission statement, that's a game changer. And all the brands that I talk to, that's where they want to go with this. They want something that they can feel comfortable, that when someone finishes using their product, when someone buys their product, that that packaging is going to be consumed by the earth properly and that it's not going to end up in a landfill. So when we started this conversation, you were talking about a lot of really complicated terms that most people don't really understand. And basically what you're saying is that you're taking something that's not environmentally friendly and converting it to something that is environmentally friendly. So can you unpack that a little bit and explain, like you did when we were talking before, how packaging that we think is recyclable isn't in fact really recyclable because it shows up in the landfill, and because of the way that it's got to be made so that you can have it be recycled with the milk carton, etc. Kelly: Right, absolutely. And probably a really good place to start is ... so I graduated in chemical engineering and I did my internship, my co-op program in Louisiana, working for a polyethylene manufacturer. So it started there and it continued with the polyethylene company that I worked for afterward. And you sit in these meetings and everyone's talking about growth. The next big project to make more ethylene, to make more polyethylene, and it seems like the only way to grow was just to continue to make more. And I started to think am I the only wondering at what point have you made too much? Obviously you can't continue just to make this stuff forever. But no one every talked about that. So it seemed like I was the one wondering where does that become? Where does it level off to where we're not creating more? And you look, from 2000 to 2010 we created more plastics globally or as much plastics globally as we did the entire previous century. So we're creating such an alarming amount of plastics, a third of that, goes into single use. Which is your granola bars, your bag of chips. And that material became the materials that we're talking about, the polyethylene, polypropylene, polyesters, because they're cheap. And they run fast, and they do all these great things. They protect the food, but there's no place for them to go afterward. You can't recycle them, and they just become a burden. You just can't contain them like you can at least more easily with rigid than you can flexibles. So there's this big movement towards we're going to make flexible packaging recyclable. Well, that's a fallacy. In fact, I'd say it's more than a fallacy. It's a fool's errand. And I'll tell you why. Because to make flexible packaging recyclable you make it have enough of what's called high-density polyethylene, you have to put enough of that into it so that it becomes compatible with what little bit of consumer products do get reprocessed, which is like your laundry detergent bottles, your milk jug bottles, those to some extent ... I don't know what the exact percentage is, but to some extent those do get recyclable, or reprocessed we'll say. But just because you make it materially compatible doesn't mean it's actually going to be incorporated into those streams. In fact, the equipment's not capable of taking it. It will actually bind the equipment up. So what you think you're doing, the right thing, it's actually just going to the landfill. Because China's no longer taking it. And that was the big change that's happened recently is China no longer takes ours and the rest of the developed world, they're no longer taking our trash, basically. So there's no place to put it. So even if you were to take some percentage, and right now I believe the number is between nine and 11 percent of single use plastics actually do get recovered and reprocessed to some level. That's not a very high level. So let's just say that you were able to do that. The reality is you will never take a beef jerky package and turn it into another beef jerky package. You're not going to do that. It's going to end up being a dog Frisbee or Ikea furniture. And I love Ikea, but there's just not enough furniture to consume the volume of plastics that we're talking about. So it's not recycling, Daniel, it's refurbishing. And we hear the term circular economy a lot. Probably now as much as we hear the word sustainability. But this is not a circular economy, it's more like a downward cyclonic non-economy. Because people have to make money in this process. And it's very hard to do that when you're making dog Frisbees. Dan: Well said. And I love the fact that you brought up your beef jerky example again, because I don't think people think about that. We are led to believe as consumer that because it's recyclable we put it in a recycle bin, and then it magically appears in another product down the road. The reality is, and just to reemphasize this again, a lot of that was going to China. Now if you stop and think about how ridiculous that sounds, here we are, a product that is trying to disrupt the category, trying to change the world, that has got really great ingredients in it, consumers like it, etc but because we don't have the capacity to recycle it on our own, we're actually spending the diesel and the man hours and everything else to put it on a boat and ship it to another country to recycle it, because we can't do it. That's not sustainable. In addition to that, think about how the brands that are trying to reduce their carbon footprint are actually adding to the carbon footprint. My point is this: when you really think about what it is, what your brand is, what your brand mission is, what do you want your brand to stand for. One of the things that I really love about one of the presentations that you shared with me is the last thing you want is to see your brand on the 6:00 news, your product getting extracted out of a dolphin or something like that. And the notion that a lot of these products end up in the ocean, a lot of these products end up in places where they're not being recyclable, where they actually can't break down, etc. Can you go into that a little bit more please? Kelly: Yeah, absolutely. In fact, interestingly I just got sent a link to a short story of someone who found a Doritos bag that had washed ashore and the date on it was 1979. And the question was well, wasn't that cellophane? Because that was about the time it transitioned. Well, it wasn't cellophane, it was just after the industry started converting to polypropylene, and the bag for being 40 years old, floating in the ocean, it is in practically mint condition. Even the inks looked great. And so that's the problem, right? So in order for us to feed nine billion people, and we are approaching nine billion people, and the third world countries that we're kind of blaming for a lot of this garbage that's going into the ocean, well look, they're not getting their laundry detergent in the big Costco sizes that we do, they're getting everything in individual sizes. And that's flexible packaging. So there's just no place for it to go. So you just can't change human behavior. That's one key thing. But when you look at ... so when you look at the population rising, the developed world getting access to more consumer products you realize just why flexible packaging is ubiquitous in society. Because its benefits are undeniable. You cannot feed nine billion people without flexible packaging. However, if that flexible packaging poisons or damages the soil that you grow the plants that you process to put into that package, or you grow the crops that feed the animals for which you process to put in that package, you can't continue. That is unsustainable, because not only are we what we eat, we are what we eat from the soil from which it ultimately began from. And as these plastics do eventually break down, they turn into micro particles. Tiny little particles of plastic that end up in the microorganisms in the sea, the crustaceans that fish eat, and it goes all the way up to whales eating 70 pounds of plastic that they remove from them and it ends up all over Instagram. So globally, consumers are very worried about this. They're very concerned, and they're looking for information. I have friends personally, millennial moms that refuse to let their babies have applesauce out of a spouted pouch because there's no place for that pouch to go. They want something that's safer. So there's this movement towards the belief system that recycling is going to fix all this, where in reality it's not because it requires a change in human behavior. Which is just not going to happen. But we've got decades of accumulation already of plastics that ... it's like don't start cleaning up the ocean until you stop it from going in. It's like trying to scoop water out of a boat that's got a big hole in it. Plug the hole, and then scoop out the water. Dan: Well said. Kelly: Now I agree that we do these simultaneously, but that's the problem is we're not really addressing the source of the problem. When you buy that granola bar, or you buy that chocolate bar from your favorite brand, or you got a discount and you get it, it's on sale, that package has served a purpose of getting it from a packaging facility to you buying it. After that, it serves no purpose. None. Zero. But that package is a very important part of the brand retail consumer equation that we're kind of missing the importance of that part of the equation. Because there's a belief that ... it's almost like sustainability today, it's lost its meaning. So sustainability has got a lot of gray area behind it. I'm wondering if today it isn't ... for some brands and retailers alike, and I'm not picking on anybody in particular, but I think there's a general trend towards sustainability meaning managing liability. Because they have to continue to grow. A brand does not grow unless they grow sales. And you do not grow sales without SKUs. SKUs are the vehicle to grow sales. All of it involves packaging. That's the fundamental question that brands have to ask themselves. Dan: Well, I appreciate you saying that because that's so critically important. One of the other things I think you might want to include while you're talking about this is the fact that we are very impatient. We want what we want, and we want it yesterday. When I was younger ... I'm a little bit older than you are ... we weren't a throw away society. And now a lot of the items that we buy today, we buy and just simply throw away. It's cheaper to just throw them away and buy a new one than it is to fix it. Think about printers now. This drives me nuts. You can actually buy a printer in most cases cheaper than you can buy the replacement ink for the printer you have, which doesn't make sense to me. Because we're creating more trash, we're adding to this problem. So now that we're talking about packaging and why this matters so much, like you said, the packaging is a representation of your brand. Shouldn't that representation of your brand include a value benefit? You know, you're trying to give back, you're trying to do something for the community, for society, etc, but shouldn't you also be thinking about what is the life of that packaging after someone finishes that single use, and wouldn't it make more sense if it was earth digestible. And that's one of the technologies, Kelly, that you shared with me. Love that terminology. Can you talk about what is earth digestible, how does it work and why should we be paying attention to this? Kelly: Absolutely. Because I think that's where there's been the hangup. So it's either recycling or compostability. And compostability means there are thousands of industrial composting centers all over the country. And you hear comments well, my neighborhood doesn't even collect compost, or my composting center doesn't take packaging. But the brands that are leading this, they stand behind something very simple. They can't control human behavior, they can't control legislation, but they have 100 percent control over what they choose to put their product in. And they want to put their product into something that they know is environmentally friendly. And they do believe that over time enough of the other brands are doing this that all of those things will work themselves out. And then you talk about well, what does it mean to be compostable. Because when people say, well is it biodegradable? That's not really a good word to use because there's really no technical definition. I mean, technically your house is biodegradable. I mean, if you let your house sit long enough, the earth will take it over. But compostability means that it goes into a set of conditions for which to create compost by the metabolism of microorganisms digesting that material and turning it into useful organic material that you can then use for farms, planting, whatever. So the problem is there's industrial conditions, backyard, and then a lot of talk about marine degradation. Well, the problem with creating a certification around marine is it can change ... you know, you go ten meters deeper, the microorganism content can change, and the makeup can change. You go a mile east or three miles west, it changes. So it's very difficult to replicate a set of conditions that could be used for certification purposes. It's very difficult to emulate these varying worldly conditions. However, you can develop packaging from materials that are by design earth digestible. Which means microorganisms will colonize on them and they will start digesting it as food. And their byproduct is safe for the environment. And as long as you're building materials or building packaging from those materials you're in a good place. Because the earth really doesn't care when or where it digests the packaging so long as it can. So if it ends up in a landfill, it's still going to digest. If it ends up blowing down the interstate, eventually it's going to be digested. If it ends up in a river or the ocean, eventually it's going to be digested. And the amount of technology and research that's going into ... basically what we're looking at is unlocking the keys to nature. So we're taking materials that nature has already made for us and turning them into useful products, like packaging, like high barrier film so you can see the product. Or you don't need to see the product. But it provides the same function. Otherwise, we're going to have no choice but to go back to where you're wrapping your meat in wax paper with a twine string and carrying it home every day. But right now, you can actually get packaging that looks every bit like the packaging that can float for 40 years and look basically untouched, yet it is earth digestible. You can now get that. So you can have your cake and the earth can eat it too, but it does come at a higher cost. Dan: So let me frame this conversation. When you think about a natural product, the ingredients that you read on the label are simple, easy to pronounce, things found in nature. No fancy chemicals. They're simple, easy to understand ingredients that people are familiar with. Essentially what you're saying, Kelly, is that we're going to be able to make packaging, or rather we have the ability to make packaging, out of something that is simple and easy to understand that we know is not harmful, we know was not cooked up in a laboratory. Right? Kelly: Right. And it runs on the same equipment that already exists. Dan: Which is really cool. So with that said, now let's talk about one of the other, as you call it, big conundrums. And that is if I'm a brand and I want to put a package on a shelf, I've got to order the packaging, I've got to wait 'til it comes in and I've got to then put the product in it and then take it to retail. This whole elaborate process could take months but if I'm a brand, I go raise a bunch of money. And as soon as I raise that money, my investors, the bank, whoever it is, is going to start expecting me to pay them back or expecting a return for their investment. However, I take the money, I invest it into the packaging, but then I'm not able to actually put the product on the shelf for many, many months after I get it, and you'll talk about that in a minute, I'm going to ask you to get into that, but more importantly, now I've got a product that I'm buying more film than I need and if I make a package change or I change something on the package, then I've got to go back to square one and start over again. Can you talk about the current supply system in terms of what it's like today for any brand that wants to have packaging created and then can you also please contrast what it's like for a small brand that wants a small order as opposed to a big brand that runs hundreds of thousands of bags a month or a week? Kelly: Absolutely. So that's really the structural supply chain being completely out of sync with the consumer-driven value chain as we see it today. So there's roughly 400 companies, I think, according to the Flexible Packaging Association data that make packaging. I'd say probably less than that are actually making the kind of packaging that we would be touching on the store shelf. But there's about 15 to 20 of those companies that make up 70% of the market. And these are companies that keep getting bigger. And the way they make packaging is they take a layer of plastic that basically will last 40 years in the ocean, such as polyester, polypropylene, and they print the graphics, they print the ink on the other side of the film and then they glue it to all the other functional layers. And that process has been practiced forever, and that's the way that they do it. And from start to finish, because every single time, even though they've printed that same job 20000 times, they are custom manufacturing every single run because they start with the printing process. And then they assemble everything. So it takes eight to 12 weeks, probably closer to 14 to 16 weeks depending on how big of a customer you are, to get packaging. So when it takes brands six months to come up with one idea they can take to market, because obviously brands can't take all their ideas to market today, right, well to me that's got a time limit. There will be a point in time that they can take all of their ideas to market as often and as frequently as they want. But today they can't. So by the time they realize what they want to take to market and they get the packaging, it takes the bigger the CPG, it takes them a year to launch a new product per category because of how much time it takes to do all of those things. Dan: Yet you were also talking about how if you're a small brand, with the new technologies that you were sharing with me and this is the part I love the most, you can effectively have print on demand packaging, which allows me to create a package, put a product in it and get it to market really fast. Now okay yeah, it does cost more but think about the amount of time, the amount of money you're wasting having that product sit, having the packaging sit in a warehouse or coming over on a ship or whatever, not being able to use it. Think about all the sales that you're not getting while you're waiting for the packaging to come in and the product to be put in it. So can you please talk about print on demand, why it's relevant compared to what small brands need to go through today. Kelly: Absolutely. So the way packaging is made today, these are essentially waste factories. So they will go through thousands of feet of material just getting something set up to run. And you mentioned printing, we're approaching a point to where nothing's going to be printed the same way twice. So you have all this waste and then you're using an entire layer of film just to do nothing more than carry ink, yet you're seeing this creation of these smaller packaging manufacturers that are setting themselves up regionally to where they can take pre-constructed. So where it's kind of like the FedEx Kinko's model. When you send a job to FedEx Kinko's to pick up your 12 binders for tomorrow's meeting, somebody doesn't jump in a van and drive over to the nearest city, to a paper plant, and start dye-cutting different sizes of paper to bring it back to print. No. Everything that they need are stacked neatly in shelves as reams of paper. That's what they print. And when you look at all of packaging, if you're a ... and at my level you'd realize that there aren't that many reams of paper required to make the functional package do what it needs to do for all of these different categories of food and non-food products. By having it pre-constructed you can take it, image it, because every ... no matter if you're an emerging brand or an SMB, a small/medium sized business, or a large CPG, I don't believe there's every been a project that's ahead of schedule. They're always behind schedule. So they don't know what needs to be printed until it's already behind schedule. So why would you do the printing first. You would do everything you possibly can short of actually knowing what you need to image onto that product. And that requires pre-constructing and then surface imaging. So it's like separating functional packaging from package decoration. If you just think about it in those terms, you realize that you're already there. And, now I'm not wasting thousands of feet. I'm not using an entire layer of costlier film to do nothing more than transport ink. I don't need to do that any more. There's other solutions that just simply didn't exist decades ago, when all of this got started, that do exist today. But we're dealing with an ingrained base of converters, manufacturers that that's the way it's done. And I think there's a predictability piece to this, too. So let's say I'm a major CPG and I make a blueberry cereal bar, and I sell four million cereal bars every week in a particular region of the country. We should expect to be approaching a point in time to where that predictability is just not there. Just like CPG's can't plan for their growth based on census data any more. So you have to realize that the future of the food industry are emerging brands. They may not have the majority of the market share, but they certainly have the majority of the market growth. And they're the ones that we need to feed. And what they want is better packaging. So if you think about how do I take packaging and turn it into a profit center versus worrying about it being a cost center, that's where the digital print technology comes in. So digital printing is not about putting a Green Bay Packers helmet on a bag of tortilla chips. You can do that, and that's awesome, and I love it. My wife's from Wisconsin, so I'll buy my bag of Packers tortilla chips. But digital printing is about track and trace and managing the entire supply chain at the unit level. So if you really want to know where your mushrooms came from on your frozen pizza, you can now do that because it all starts and stops with that package. That package becomes the unitized envelopment of the product for which you can tie all of that information together. All the way to the consumer. Because right now brand doesn't have that direct relationship with the consumer. And now they can. So with things like Sidekick and all these other great software technologies, when the consumer zaps that granola bar, they don't even know where the QR code is, it's just hidden in the graphics. But it's going to know who they are. It's going to know their background, their ethnicity, where they live. They're going to know all this, and they're going to tailor a message directly to them. They can offer promotions, they could even what I call truth to power. So truth to power is where when you really want to make change you have to get enough people ... the constituency, the people that actually vote to say we want you to do something. So if you want to start changing industrial compost centers to take packaging, why not make that granola bar scannable that takes you to a place where you just enter your information and now you've got eight million signatures saying hey, State of California, we want you to subsidize composting centers to accept packaging. That's truth to power. All that can be done with packaging. Daniel, we spend far more time interacting with packaging than we listen to radio commercials, we watch TV ads, or we wait one second longer than we have to to click out of something on YouTube. But we are looking at packaging, individually, uninterrupted, all the time, every day. Dan: I want to go one step further. If you're voting with your dollars ... and I agree with you completely ... I think what's really going to change this industry, if you're looking at natural organic brands which are driving sustainable growth across every category, it's that consumers are going to vote with their dollars. They're going to make a conscious choice to buy products that are in packaging that completely disintegrates, that are completely earth digestible. The point being is that that's how you force world change. Without even waiting for the government to get involved. And those are these small brands, the ripple in the pond, those are these small brands that are affecting that change across the entire landscape. I appreciate you sharing all this, Kelly. Is there anything else that we should know about sustainable packaging from you, and why this is important? Kelly: You know, it may sound heavy but I truly believe that the future of society, of our ability to continue societally speaking on the path that we're on, where we can go to the grocery store and we can get products that are packaged that have a year shelf life, and we can enjoy the fact that we can get iceberg lettuce year round, that we can get strawberries year round, and all of those things that allow us to enjoy that are at risk. Because if we don't take care of this problem, we're not going to be able to do that. And I don't think we're set up to be able to manage that when it happens. So at some point, we have to address the problem. And to me recycling is just simply a fool's errand. I think rigid has a greater chance because it doesn't blow away, it's denser, you don't have to worry about ... so store take back, stores will take back packaging. For one, for flexibles, you have to clean it. So let's say that I'm going to ... I would have to have a separate room in my house to start collecting all of my granola bar wrappers 'til I had enough, then baled it, compacted it and baled it to where I took it to the store to make sense to even take it. Otherwise, I'm just going to throw it in the garbage. Just the term throwing it away, where is away? Do we ever think about where away is? Dan: Right, and if you think about cleaning the packaging, remember we used to, when recycling first started, you needed to clean out the can? So what chemicals might you be using to clean out the can so it's nice and shiny and clean so that you can recycle it? Or how much water are you wasting? And those are things that need to be considered as well. So I think it's ridiculous to think that consumers are going to save up a bag or a box or whatever of granola wrappers and a box of chip wrappers and a box of whatever and then take those back in. Because remember when we started doing recycling, we had to separate everything out. And consumers just don't have the time or the patience to do that. So the notion of being able to have earth digestible packaging that we don't need to worry about this, that's the future, and that's the opportunity. Again, thrilled that you're sharing this. The exciting news that I wanted to share is that you and I are collaborating to bring this information to the masses. And so from your perspective, you're bringing the technology, the strategies behind how to create the earth digestible packaging. I'm bringing the strategies in terms of how does a brand leverage this at retail and with the consumers to help more retailers ... or as I would say to help get your brand on more retailer shelves and in the hands of more shoppers? So what we've done is Kelly and I have collaborated on a mini course to teach brands about this, to teach brands about how this works and why this is important. And one of the great things about it is that there's going to be a lot of great information that it's going to walk you through and show you and illustrate to you why this matters exactly. And how you can be a part of the solution and not part of the problem. And even better yet, this course is free. It's our way of giving back and it's our way of helping you make a bigger difference or bigger impact in this industry. So I'm going to put a link to that at the end of the podcast. But it's brandsecretsandstrategies.com/packagingsolutions if you want to go there instantly. But like I said, I'll put a link on the podcast webpage and in the podcast show notes. Kelly, I really appreciate you coming on. Is there anything else that we should have mentioned today that we didn't cover? Kelly: Just what you just said. The way I look at it, we're trying to change the industry from the materials side of things, from the way things are manufactured. But there's this whole, rich universe on the other side of that fence, which is the category management, the how you get a new product to market, the path that you get it to market. All the things that Daniel, you're so focused on and yet you're focused in the same direction, which is emerging brands and helping them be successful and navigating that space, which we believe as well. So I think in working together we can only add more value to those brands. And the educational platform that you developed is just amazing. I have learned so much- Dan: Thank you. Kelly: -from your courses that it's like a whole world ... so it's like when people listen to me talk about my world and they're like wow, this is great. That's the way I feel when I'm going through your world. So I think we compliment extremely well, almost like a zipper that needs to be zipped up, and it's time for that to happen because the only way we're going to help these brands deliver what consumers expect and all the way from the product itself to the packaging is by working together to make that happen. Dan: Absolutely. We all rise together. So thank you for sharing that. So Kelly, thank you so much for sharing. I really appreciate you making time for me today. Kelly: Thanks, Daniel. Always my pleasure. Dan: I want to thank Kelly for coming on today, and for making this very complicated topic a lot easier to understand. Packaging is one of the most important things that every brand needs to focus on. It's one of the most intimate and personal things every brand needs to think about as they develop their go to market strategy. Your packaging is a reflection of your brand. Make it a good one. In the free mini course that's associated with this podcast, you're going to learn what you need to know about sustainable packaging, what recyclable packaging is and isn't, how packaging should be an extension of your brand and your brand mission, how you can leverage the strength of your mission which includes your packaging, to grow sustainable sales at retail. You will also learn creative strategies about print on demand packaging, something that's going to be a game changer in our industry. You're going to learn how to get your product on a retail shelf much quicker than traditional methods available today. The last thing that any brand wants to do is spend months and months waiting for the packaging to come in before they can get their product on the retailer shelf. You can learn more about this free course at brandsecretsandstrategies.com/packagingsolutions. I'll also include a link to Futamura in the packaging course, in the show notes, and on this podcast webpage. You can there by going to brandsecretsandstrategies.com/session116. Thank you for listening and I look forward to seeing you in the next episode. This episode's FREE downloadable guide The great equalizer between small and large brands. Learn how it has evolved and the advanced strategies that retailers really want and need from you and your brand. CLICK HERE TO DOWNLOAD YOUR FREE STRATEGIC GUIDE: What is Category Management and Why It's So Important Thanks again for joining us today. Make sure to stop over at brandsecretsandstrategies.com for the show notes along with more great brand building articles and resources. Check out my free course Turnkey Sales Story Strategies, your roadmap to success. You can find that on my website or at TurnkeySalesStoryStrategies.com/growsales. Please subscribe to the podcast, leave a review, and recommend it to your friends and colleagues. Sign up today on my website so you don’t miss out on actionable insights and strategic solutions to grow your brand and save you valuable time and money. I appreciate all the positive feedback. Keep your suggestions coming. Until next time, this is Dan Lohman with Brand Secrets and Strategies where the focus is on empowering brands and raising the bar. Enter your name and email address below and I'll send you periodic updates about the podcast. Sign up to receive email updates

Listen where you get your podcast

Like what you’ve heard? Please leave a review on iTunes

FREE Trade Promotion ROI Calculator:

Click Here To Maximize Sales And Profits

Free brand-building resources to help you grow and scale

Turnkey Sales Story Strategies FREE ON-DEMAND COURSE

Why Most Brands Fail – The Roadmap To Sales Success FREE ON-DEMAND COURSE

Essential In-Store Customers First Marketing Strategies FREE ON-DEMAND COURSE

How To Drive Profits With Sustainable Packaging FREE ON-DEMAND COURSE

The Retail Game – What You Need To Know With Bob Burke FREE ON-DEMAND COURSE

Sales Success Begins With A Solid Business Plan FREE ON-DEMAND COURSE

How To Turn Your OnLine Data Into Explosive Sales Growth FREE ON-DEMAND COURSE

2016 Category Management Handbook Page 20 & 21

Want A Competitive Edge? The Recipe For Success

New product innovation is the lifeblood of every brand. New products fuel sustainable growth, attract new shoppers and increase brand awareness. Know the critical steps to get your product on more retailer’s shelves and into the hands of more shoppers.

Empowering Brands | Raising The Bar

Ever wish you just had a roadmap? Well, now you do!

Don’t miss out on all of these FREE RESOURCES (strategic downloadable guides, podcast episodes, list of questions you need to be asking, and know the answers to, the weekly newsletter, articles, and tips of the week. You will also receive access to quick and easy online courses that teach you how to get your brand on the shelf, expand distribution, understand what retailers REALLY want, and address your most pressing challenges and questions.

All tools that you can use, AT NO CHARGE TO YOU, to save you valuable time and money and grow your sales today!

Image is the property of CMS4CPG LLC, distribution or reproduction is expressively prohibited.